Question: We struggle with making down our flocculant to the proper percentage/ppm range.

Robin DealThis leads to “fisheyes” in our make-down tank. The dosing pump and lines can become clogged at times with these slimy balls. It is a mess to clean up. How can we ensure that we make down our flocculant properly each time while preventing these types of maintenance nightmares?

Robin DealThis leads to “fisheyes” in our make-down tank. The dosing pump and lines can become clogged at times with these slimy balls. It is a mess to clean up. How can we ensure that we make down our flocculant properly each time while preventing these types of maintenance nightmares?

Answer: The easiest answer for you would be to switch to a ready-to-use flocculant. This would eliminate the worry of not having a proper mix and eliminate the “fisheyes” altogether. There are several reasons, however, that could prevent you from making the switch. If this is the case, and you have to stick with what you currently use, there are formulas to help you calculate the amount you need to use for your make-down tank. There is also equipment that can be purchased to help eliminate the “fisheyes.”

For those who do not know why not having the correct make down can be a problem, let me explain that first. If you make your flocculant too weak, you will not see proper floc formation in your system. This can result in a small “fine” floc making its way out your door and to the city, where you could find yourself in violation of your discharge permit. On the other hand, if you make it too strong, it will not disperse through the system properly. It will wrap around mixers and cause mats to form on top of the clarifier.

Flocculants come in three forms. When the ready-to-use form is not an option, powders or emulsions are available.

Powdered flocculants have an extended shelf life as long as they are kept dry. We recommend storing them in their original bag inside of a closed container such as a barrel with a locking lid to ensure moisture is kept out. Make-down is recommended at 0.1%-0.5% of the weight of the water in the day tank.

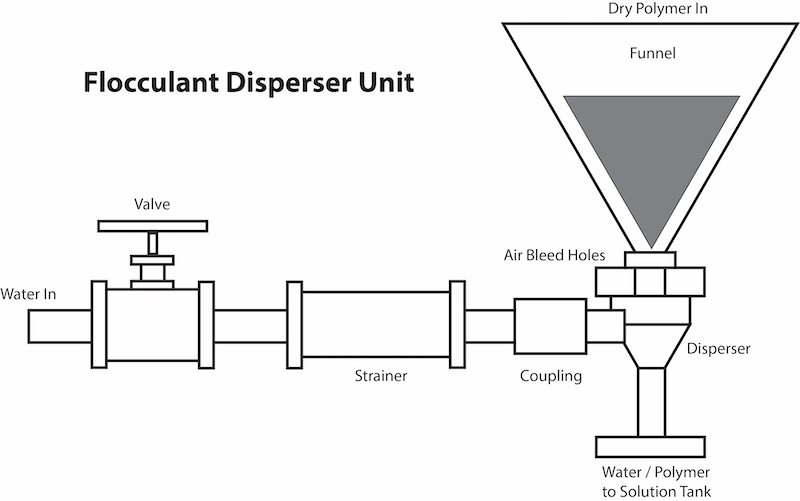

For example, 100 gallons of water would weigh 834 lbs. If we went with 0.2% flocculant, we would need 1.7 lbs of the dry flocculant added to the water. To avoid the “fisheyes,” we would suggest a flocculant disperser or educator be added. These units allow for each grain of flocculant to be prewetted before going into the tank, thus preventing the grains from sticking together and becoming “fisheyes.”

The tank should be equipped with a mixer as well. The mixer should be variable speed so that when the flocculant and water are first introduced to the tank, the mixer can mix rapidly (disperse) for 15-30 minutes, then slowed down to mix for up to a total of 120 minutes. After the flocculant is fully mixed, the mixer should be shut off and the solution allowed to age for at least 30 minutes before use.

Emulsion flocculants are flocculants that are suspended in a solution, usually a surfactant, at a 5gram per liter concentration. They have a six-month shelf life. When using emulsions, the containers they come in should periodically be mixed so that the carrier keeps the flocculant in suspension. If they are allowed to sit undisturbed, the flocculant will sink to the bottom of the container, with the carrier rising to the top. If this happens, mix the emulsion back up before use. To store the emulsion, keep it in the original container, keep the opening closed when not in use, and keep it in a cool, dry area. Recommended concentrations for emulsions are 0.2%-1% of the weight of the volume of the tank. (see above)

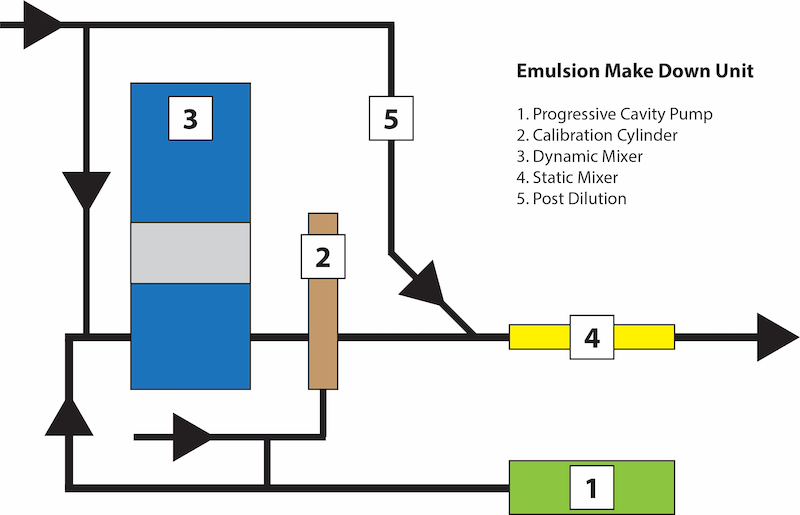

There is equipment that can be used to mix the flocculant with water to prewet it before going into the make down tank. These units pull the emulsion into a stream of water, allowing for mixing before going into an aging tank. If you cannot purchase these units, your make down tank should be equipped with a variable speed mixer. Fill the tank, turn the mixer to a rapid mix, slowly pour the emulsion into the vortex created by the mixer, allow the emersion to disperse by rapid mixing for 0-15 minutes, then slow the mixer down and allow to mix for an additional 15-30 minutes. Turn the mixer off and allow it to age before use.

A quick visual check that operators can use to ensure the flocculant is ready to use is:

- While wearing gloves, touch the solution with your forefinger

- Touch your forefinger to your thumb

- Slowly separate your forefinger from your thumb while watching the strand of flocculant

- The strand should break at roughly a 45-degree angle

If this happens, the flocculant is of the proper strength and ready to use. If the strand breaks quickly without the 45degree angle, allow the solution to age a little longer and try again. If it is still breaking early, it is possible it was made down to weak and will require more solution to see the correct floc formation in the clarifier. If it does not break or breaks at more than a 90-degree angle, it is made down too strong and can be diluted with additional water for use.

If you happen to spill the flocculant, do not use water for clean up. Water will only make the spill slippery and unsafe. If it is in powdered form, sweep up the powder and dispose of it properly. If it is in emulsion form, use oil dry to soak up as much of the moisture as possible. Dispose of this. Use a weak bleach solution to break down any residue remaining on the floor.

Robin Deal is a Product Leader for Aquapure at Hubbard-Hall. Please visit www.hubbardhall.com