Short-circuiting is a condition that occurs when water flows along a nearly direct pathway from the inlet to the outlet of a tank or basin, often resulting in shorter contact, reaction, or settling times in comparison with the calculated or presumed detention times.1

Robin DealWhen short-circuiting occurs in a wastewater system, several issues are seen.

Robin DealWhen short-circuiting occurs in a wastewater system, several issues are seen.

- Chemical reaction time is shortened as the wastewater is not in the tank as long as intended.

- Chemical usage can increase as a means to overcome the shortened reaction time.

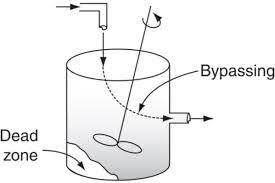

- Dead zones, areas where no desired reactions occur, can be created.

- Solid settling in tanks not designed for settling can happen.

- Carry-over or pass-through of contaminants can happen.

If short-circuiting of a tank is a possible issue for a wastewater system, what can be done?

Not Getting Full Retention of Wastewater

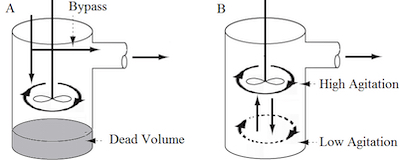

Non ideal, real mixing scenarios; A: Bypass with dead volume, and B: Rapid and slow mixing.The first step is to determine if the tank is, in fact, not getting full retention of the wastewater. The Hydraulic Retention Time will need to be known. The HRT refers to the length of time wastewater will stay in a tank during a treatment process.

Non ideal, real mixing scenarios; A: Bypass with dead volume, and B: Rapid and slow mixing.The first step is to determine if the tank is, in fact, not getting full retention of the wastewater. The Hydraulic Retention Time will need to be known. The HRT refers to the length of time wastewater will stay in a tank during a treatment process.

Let’s take a system flowing 100,000 gallons per day. It has a tank with a volume of 5,000 gallons. What should its HRT be?

HRT = 5,000 gallons / 100,000 gallons per day

HRT= 1.2 hours (or 0.05days)

Now that the HRT is known, a tracer test can be run to determine if the tank is short-circuiting.

Hydraulic Behavior in an Activated Sludge Tank From Tracer Test through Hydraulic Modelling to Full-Scale Implementation.Tracer testing is conducted by putting a tracer dye into the tank in question at the influent point for that tank. Time how long it takes for the dye to move from the tank in question to the next tank in the treatment process. If the tracer dye moves as it should, and there is no short-circuiting detected, then the problems the system is seeing are not related to the tank dynamics.

Hydraulic Behavior in an Activated Sludge Tank From Tracer Test through Hydraulic Modelling to Full-Scale Implementation.Tracer testing is conducted by putting a tracer dye into the tank in question at the influent point for that tank. Time how long it takes for the dye to move from the tank in question to the next tank in the treatment process. If the tracer dye moves as it should, and there is no short-circuiting detected, then the problems the system is seeing are not related to the tank dynamics.

Determine What is the Cause

If short-circuiting is proven to be an issue, what can be done about it? The first step is to determine what is the cause.

Short-circuiting can be caused by:

- Tanks may have had baffles in the original design, but they were left out during the build.

- Hydraulics may not have been considered during the design phase.

- Liquid and solid flow through a system may not have been fully understood during design.

- Improper mixing due to shortened shafts on the mixers or incorrect rotation of the shaft and propellers during mixing.

- Solids build up in tanks.

Fixing a short-circuiting issue could be done by:

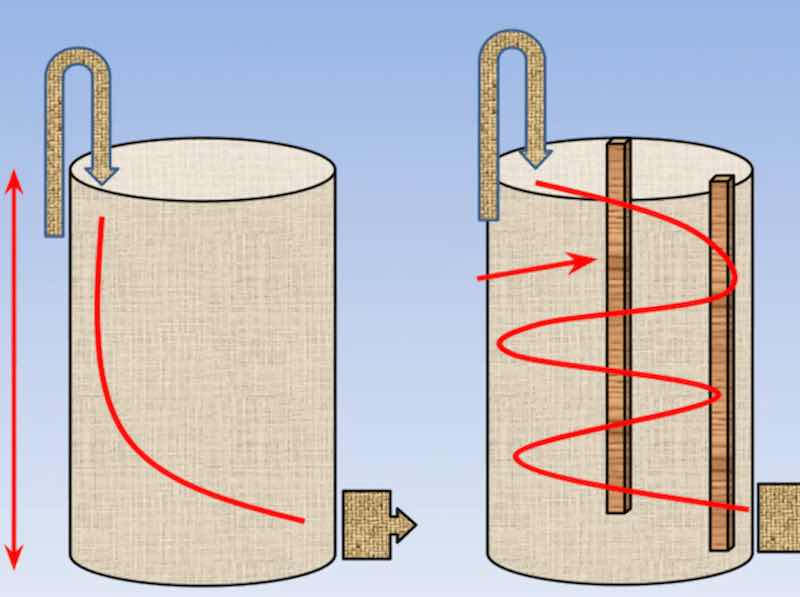

- Adding baffles to slow down the wastewater flow.

- Adding a recirculation pump to a tank increases retention time.

- Clean out tanks to ensure solids are not collected in the bottom.

- Correct mixer length and/or rotation if needed.

- Adjust inlet and outlet pipes to add additional retention time.

As always, if you have questions about your wastewater systems' overall effectiveness, consult with the equipment manufacturer or your chemical supplier for assistance with understanding how your system should be performing.

Reference

- Sacramento State University, Office of Water Programs.

Robin Deal is the Product Manager for Aquapure at Hubbard-Hall. Reach her at rdeal@hubbardhall.com or visit www.hubbardhall.com.