As weld nuts have a thread in them, it is important to ensure that the thread does not get powder coating or surface finishing on it. Specially designed weld nut plugs are available to mask weld nuts quickly and efficiently.

Weld nuts are a special type of nut that is commonly welded to fabricated parts, often because the fabrication itself is not thick enough to be threaded. There are several types of weld nut. Some of the more common types are: round base nuts, which have a long threaded cylinder and large circular base; slab base nuts, which have a rectangular base.; hex weld nuts, which look like a regular nut with an added locating boss and lugs on one face and retainer weld nuts, where the nut can float within a retaining cage. There are numerous tab-style weld nuts, which again look like a regular nut, but have one or more tabs on them to weld the nut in place.

Despite what seems like an endless list of different styles of weld nuts, the common thing in terms of surface finishing is that they are all threaded, and in most cases that thread needs to be protected from surface finishing.

Despite what seems like an endless list of different styles of weld nuts, the common thing in terms of surface finishing is that they are all threaded, and in most cases that thread needs to be protected from surface finishing.

A simple way to mask weld nuts is to push a tapered plug into the threaded hole. This will generally work, although it will not completely mask both ends of the threaded portion of the nut. It will certainly not completely mask the first portion of the thread where ultimately, on assembly, the bolt will be started into the nut. Ensuring the threaded portion of the nut, and in particular, the area of the first thread, is masked correctly is crucial on a weld nut.

Besides not covering the complete thread or the first thread, long tapered plugs can also be problematic during the pre-treatment process. A lot of fabricated parts are shot blasted prior to surface finishing and it makes sense to mask the part prior to shot blasting. During the blasting process, long tapered plugs may come out and shot material may then enter the threaded hole, damaging the thread or lodging inside the threaded hole. If the part is then painted with remnants of shot in the threaded hole, the paint will bond with the shot and form a solid lump on the thread. If that happens or the thread is damaged, then the weld nut will require tapping out at a later stage of the process.

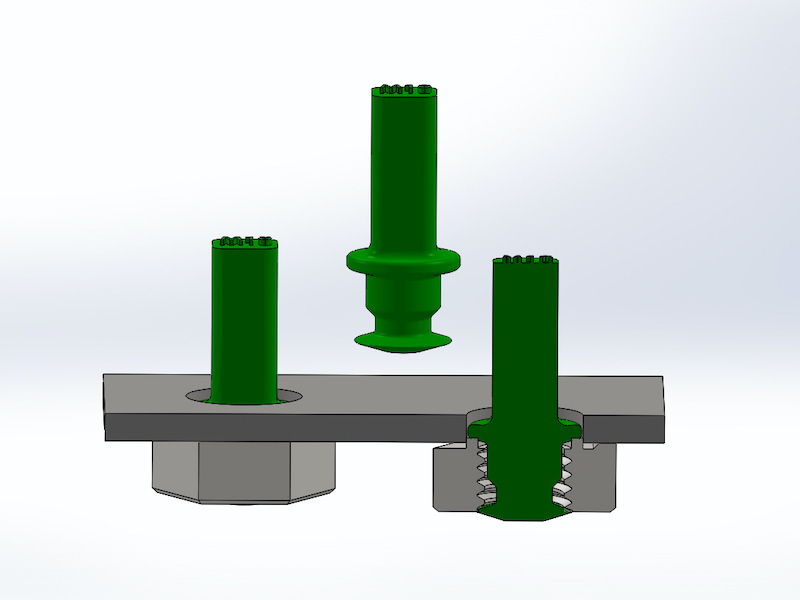

That is why it is better to use a plug specifically designed to mask weld nuts. Two styles of weld nut plugs are available, a simple push-in style plug or a pull plug style that is pulled into the hole. Both styles protect the threads. Both styles have a low-profile shaped handle to ensure the plug can be installed and removed quickly without the risk of the handle being a drawback in the pre-treatment or finishing stages of the process. Usually, the plugs are color-coded and engraved to identify the size.

To explore masks for weld nuts further, contact a masking company such as Caplugs, and ask them for samples so you can test the plugs in your finishing process.

John D. Gill is an Engineer with Caplugs Inc. John has experience in masking and surface finishing throughout the UK, Europe and the USA. He works with Caplugs manufacturing facilities in the USA, Europe and China.