The term “stainless” as it applies to stainless steel is misleading, as many think that stainless steel cannot corrode because it is stainless.

Frank AltmayerThe correct term should be “stains-less but still may corrode steel.” Another term used for stainless steel is CRES (corrosion-resistant steel).

Frank AltmayerThe correct term should be “stains-less but still may corrode steel.” Another term used for stainless steel is CRES (corrosion-resistant steel).

The reality is that parts manufactured from stainless steel can readily corrode because they most often have “free” iron embedded into the surface by whatever manufacturing processes, such as stamping, grinding, welding, and forging, may have been used.

There also is the issue of the “quality” of stainless steel, as there are numerous types of alloys, and compositional quality can vary greatly.

What makes steel “stainless” is the incorporation of at least 11.5% chromium into the iron-carbon (steel) alloy. The most corrosion-resistant stainless steels will also contain significant percentages of nickel, and some alloys contain additional alloying elements such as molybdenum and vanadium. A general rule is that the higher the chromium and nickel content, the higher the quality (corrosion resistance) of the stainless steel alloy. Chromium and nickel are metals that naturally form an oxide layer when exposed to air, and it is this oxide layer that acts as an effective barrier to many commonly encountered corrosive environments. However, this oxide layer can be compromised by acidic environments containing halogens such as fluoride, chloride, and bromide. Stainless steel is typically not considered suitable for applications in which these ions are present. Hydrochloric acid, for example, is well known to cause intergranular attack, and chloride ions are well known to cause stress corrosion cracking of stainless steel. There are some proprietary stainless steel alloys designed to resist this type of corrosion.

When stainless steel is subjected to high-temperature conditions such as a welding operation, the chromium may migrate to grain boundaries, forming carbides. The reduction of chromium due to the formation of carbides can make welds significantly lower in corrosion resistance. Alloys containing <0.03% carbon are preferred for welding for this reason.

When stainless steel has free iron embedded into the surface, a galvanic cell is produced, in which the free iron is the anode and the stainless steel is the cathode. Depending on the alloy, the cell voltage is between 0.1 to 0.3 V (316 and 600 series stainless produce the higher voltages). When exposed to an electrolyte such as a salt spray mist, the battery is completed, and the free iron quickly (often within minutes) begins to rust.

Consider the spoon in the accompanying photo. It was made by cladding two layers of 400 series stainless steel together, but a manufacturing defect caused the layers to split, creating a thin, unnoticeable cavity (In the photo, we have separated the layers to show the corrosion.). This thin cavity soaked up liquid as the spoon was used (by one of my friends to eat soup in a restaurant). The trapped liquid between the stainless steel layers acted as an electrolyte, completing the battery. In addition, the thin crevice produced an oxygen-concentration cell. The end result was severe corrosion between the layers of stainless steel and bad-tasting soup, which my friend asked me to investigate (he refuses to eat there again).

Consider the spoon in the accompanying photo. It was made by cladding two layers of 400 series stainless steel together, but a manufacturing defect caused the layers to split, creating a thin, unnoticeable cavity (In the photo, we have separated the layers to show the corrosion.). This thin cavity soaked up liquid as the spoon was used (by one of my friends to eat soup in a restaurant). The trapped liquid between the stainless steel layers acted as an electrolyte, completing the battery. In addition, the thin crevice produced an oxygen-concentration cell. The end result was severe corrosion between the layers of stainless steel and bad-tasting soup, which my friend asked me to investigate (he refuses to eat there again).

Let’s delve deeper into some of the more commonly encountered stainless alloys.

200-300 (Austenitic) Grade Stainless Steel

The vast majority of stainless steel manufactured is of the 300 series variety. These alloys contain nickel and or manganese to stabilize the austenitic crystal structure. These alloys are non-magnetic and contain a minimum of 16% chromium. The carbon in these alloys adds strength and hardness. The alloys can be heat-treated to yield additional hardness. 300 series alloys offer excellent service under very low-temperature conditions.

The vast majority of stainless steel manufactured is of the 300 series variety. These alloys contain nickel and or manganese to stabilize the austenitic crystal structure. These alloys are non-magnetic and contain a minimum of 16% chromium. The carbon in these alloys adds strength and hardness. The alloys can be heat-treated to yield additional hardness. 300 series alloys offer excellent service under very low-temperature conditions.

These steels exhibit superior corrosion resistance in a wide range of environments. The properties can only be modified by cold work. They are also significantly more expensive than the 400 series stainless grades. The thermal expansion of 200-300 series stainless steel is close to copper, but the thermal conductivity is extremely low.

Some popular alloys in this grade are:

303 (<0.15% C, 17-19% Cr, 8-10% Ni, <2% Mn, <1% Si, <0.2% P, >0.15%S)

This alloy typically contains enough sulfur and phosphorus to make it easier to machine vs. 304. It is a commonly used alloy in screw machine applications. The high sulfur content also contributes to resistance to galling (cold welding of stainless steel when mated to itself using fasteners). The 303 alloy is less corrosion-resistant than the 304 alloy.

304 (17.5-20% Cr, 8-11% Ni, <2% Mn, <1% Si, <0.45%P, <0.03%S, <0.08%C)

This is the most commonly encountered stainless steel and is also known as “18/ 8” stainless steel. The crystal structure allows this alloy to be deep drawn without intermediate annealing. Commonly manufactured parts include kitchen sink tubs, hollow ware, and saucepans (304DDQ). This alloy can readily be welded. Postweld annealing is required when welding heavy sections of the 304 alloy but is not typically required with the 304L (low carbon) version. 304 also comes in a high-carbon version (304H) for high-temperature applications.

316 (16-18.5% Cr, 10-14% Ni, 2-3% Mo, <2% Mn, <1% Si, <0.45%P, <0.03%S, 0.03%C)

The main difference between 316 and 304 stainless is the molybdenum content. Molybdenum increases the resistance of the alloy to attack by corrosives such as chloride. The 316 alloy is considered to be superior to 304 in almost any corrosive environment. This alloy can readily be welded. Post-weld annealing is required when welding heavy sections of the 316 alloy but is not typically required with the 316L (low carbon) version. This alloy is commonly found in food contact and in many medical applications.

400 (Ferritic) Grade Stainless Steel

These alloys can easily be differentiated from the 300 series by their magnetic properties. They contain between 10 and 27% chromium and only 0 to 2% nickel. Some ferritic alloys contain molybdenum (e.g., 29Cr 4Mo). While some alloys may be highly corrosion resistant, the lower chromium alloys typically are poor in all but the most benign environments. Commonly encountered 400 series alloys include:

These alloys can easily be differentiated from the 300 series by their magnetic properties. They contain between 10 and 27% chromium and only 0 to 2% nickel. Some ferritic alloys contain molybdenum (e.g., 29Cr 4Mo). While some alloys may be highly corrosion resistant, the lower chromium alloys typically are poor in all but the most benign environments. Commonly encountered 400 series alloys include:

420 (<0.15% C, 12.0-14.0% Cr, <1.0% Mn, <1.0% Si, <0.04% P, >0.03% S)

This alloy contains just enough chromium to improve the corrosion resistance vs. non-stainless steel. It can be heat treated to very high hardness (Rockwell C 50). The most common use is cutlery. This alloy is poor in weldability. It turns brittle at subzero temperatures.

430 (<0.12% C, 16-18% Cr, <0.75% Ni, <1.0% Mn, <1.0% Si, <0.040% P, <0.030% S)

This is a non-heat treatable alloy offering good formability and better corrosion resistance than 420. The most common application for this alloy is decorative trim on consumer items such as appliances and automobiles.

400 (Martensitic) Stainless Steel

These stainless steels are heat-treatable due to their higher carbon content. The martensitic 400 series stainless steels are less corrosion-resistant than the ferritic 400 series alloys. These alloys offer good strength and corrosion resistance at high temperatures (up to around 750°C), contain enough carbon to make them heat-treatable as a consequence of the higher carbon content, and are known as martensitic stainless steels (e.g., 410, 416). They do, however, exhibit lower corrosion resistance due to chromium depletion of the oxide film. They exhibit good strength and oxidation resistance up to 750°C. Creep resistance above 600°C is poor.

These stainless steels are heat-treatable due to their higher carbon content. The martensitic 400 series stainless steels are less corrosion-resistant than the ferritic 400 series alloys. These alloys offer good strength and corrosion resistance at high temperatures (up to around 750°C), contain enough carbon to make them heat-treatable as a consequence of the higher carbon content, and are known as martensitic stainless steels (e.g., 410, 416). They do, however, exhibit lower corrosion resistance due to chromium depletion of the oxide film. They exhibit good strength and oxidation resistance up to 750°C. Creep resistance above 600°C is poor.

440 (0.65-1.0% C, 16-18% Cr, <1.0% Mn, <1.0% Si, <0.040% P, <0.030% S)

The higher carbon 440 alloys can attain the highest level of hardness, after heat treatment, of all stainless alloys, reaching a Rockwell C hardness of nearly 60. This stainless is commonly used for razor blades and other utensils requiring a sharp edge. The alloy comes in four grades (A, B, C, and F). The A, B, and C grades are in order of increasing carbon content, while the F grade is a free-machining alloy. The lower carbon alloys are more corrosion resistant, while the higher carbon alloys are harder after heat treatment.

600 (Martensitic) Grade Stainless Steel

These alloys are also magnetic. They are typically heat-treated to yield high tensile strength and are popular in aerospace applications. The chromium content is 12 to 14%. Other alloying elements include carbon (0.1 to 1.0%) and nickel (0 to 2%). These alloys are typically less corrosion-resistant than the 300 and some 400 series alloys.

These alloys contain elements such as copper, aluminum, and/or titanium, which form finely dispersed alloy precipitates during aging (storage for many hours at specific high temperatures). A desirable feature of these alloys is that they can be hardened at low enough temperatures to allow for hardening after forming/ machining without scale formation. Common alloys in this group include 174PH (17% chromium-4% nickel) and 155PH stainless steel.

There are numerous other alloys, including mixtures of austenitic and ferritic alloys (duplex stainless steels), but the above are the most commonly encountered.

Defining Passivation

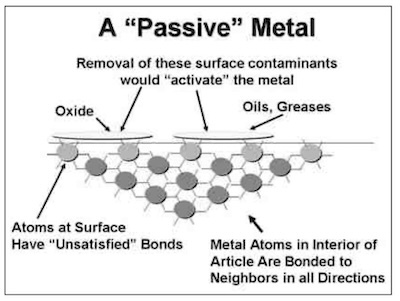

On a basic level, metals may exist in one of two surface conditions: active and passive. Consider the metal atoms shown in the figure. Each of the atoms within the bulk of the metal is bonded to neighboring atoms. However, the very last atoms at the surface of the metal are not bonded by neighboring atoms of the same metal, as on one side, there is only “air” available.

On a basic level, metals may exist in one of two surface conditions: active and passive. Consider the metal atoms shown in the figure. Each of the atoms within the bulk of the metal is bonded to neighboring atoms. However, the very last atoms at the surface of the metal are not bonded by neighboring atoms of the same metal, as on one side, there is only “air” available.

When a metal has surface atoms that are not (yet) bonded to other atoms, we conclude that the metal is in the “active” state. Converting a metal to the active state by stripping all surface atoms of any materials/ compounds present from the surface is a process that generically is called “activation.” A metal must typically be in the active state prior to any electroplating process, for example.

A metal in the active state is prone to react with any convenient atoms available for bonding. That is why freshly electroplated nickel can not stay in a rinse tank too long, as the nickel will bond with oxygen present in the rinse water, and then it will no longer be “active.” Oxygen, sulfides, and various organics are common compounds that are at least partially bonded to active metal surfaces, rendering them in the “passive” state. In general (some precious metals are exceptions), metals react with whatever environment they are exposed to, and given enough time, they will convert to a passive state.

Based on the above definition, “passivation” can be considered to be a generic term for any process that converts an active metal to a passive condition. Such processes include chromatin, black oxide, and phosphating, but most often, the term passivation is used to describe a process in which stainless steel is treated in a chemical solution that will produce metallic oxides on the surface and, at the same time, dissolve any free iron that could galvanically produce electrolytic cells that can re-activate (on a local basis) the stainless steel, yielding corrosion spots.

We covered numerous types of stainless steel alloys last month, and all of these were in the “active” state when produced by the steel mill. As the metal cooled, it became passive and may even have grown a thick layer of oxide “scale.”

Also, as parts are manufactured via stamping, cutting, forging, casting, etc., various lubricants and other organic materials will be either physically present on the surface or bonded to the surface atoms. In fact, if present, we need to remove the oxide scale prior to true passivation. The surface condition of stainless steel exhibiting the presence of scale and other residuals may generically be referred to as a passive condition. However, these materials are unsightly, promote the corrosion of stainless steel in various environments, and are not suitable for use in typical applications such as food service or medical instruments. Therefore, we would not call such a condition truly passivated. In passivating stainless steel, we need to remove scales, machining/grinding fines, and lubricants from the surface, rendering the steel in an active state, then treat the steel in a chemical solution specifically designed to passivate the surface under controlled oxidative conditions (s).

Process Steps

As just discussed, before we passivate stainless steel, we need to remove oxide scales and all other surface impurities that can impede or prevent the formation of a controlled oxidative process. We won’t discuss the details of conventional cleaning and descaling cycles employed, but here are a few general “tips”:

- Parts that have intricate shapes that may make descaling/cleaning a difficult proposition should be processed through ultrasonic cleaning as part of the preparation cycle. Incomplete descaling and cleaning will result in poor corrosion resistance. For food/medical utensils, this can be a huge problem, as the residuals can act to retain bacteria in service. For the same reason, any food/medical utensils should be thoroughly inspected after descaling to make certain that the process did not produce pitting.

- Solvent cleaning (vapor degreasing) using chlorinated solvents can lead to poor corrosion resistance if the part has an intricate shape or crevices that can trap solvent residuals, which in turn can be converted to chlorides by the passivation process. Trapped chlorides can produce corrosion spots, given enough time.

- Abrasive blasting should be conducted using iron-free media.

- Do not descale welded austenitic stainless steel in nitric-hydrofluoric acid mixtures, as these solutions can attack the weld areas.

- Visually inspect (at least some) descaled/cleaned parts before passivation. According to ASTM A380, the visual inspection should be carried out with general lighting at 100-foot candles and 250-foot candles on the surface that is being examined. Areas that can not be easily viewed should be wipe-tested using lint-free cotton cloth or swabs. On the process line, make sure that parts are water break-free before they go into the passivation solution.

- Since stainless steels are used in some highly critical applications (nuclear, for example), the specification for such critical parts will include far more cleaning, descaling, and handling do’s and don’ts than we have here.

Passivating Solutions

Nitric acid

Historically, nitric acid or nitric acid-containing chromates have been employed to passivate stainless steel.

Nitric acid – 20% to 50% vol%

According to ASTM A380, this solution at 120 to 160°F (10 to 30 min) or 70 to 100°F (30 to 60 min) is suitable for annealed, cold-rolled, thermally hardened, or workhardened 200 and 300 Series, 400 Series, precipitation hardening and maraging alloys containing 16% or more of chromium, 400 Series, maraging and precipitation-hardening alloys containing less than 16% chromium, high-carbon-straight Cr alloys (except free-machining alloys), IF the surface is dull, as some light etching may occur. For bright surfaces, ASTM recommends a nitric-dichromate mix (see below).

Nitric acid-dichromate mixes

HNO3 (20 to 40%) plus Na2Cr2O7·2H2O (2 to 6 wt%), 120 to 155°F, 10 to 30 min (or 70 to 100°F, 30 to 60 min) is preferred for the same alloys indicated above, if the surface is bright. Frankly, to avoid any chance of pitting, this would be my choice over straight nitric. For free machining 200, 300, and 400 series alloys, the temperature range for this solution changes to 70 to 120°F, and immersion times are reduced to 25 to 40 min. An alternate composition for free machining 200, 300, and 400 series alloys is HNO3 (1 to 2% plus Na2Cr2O7·2H2O (1 to 5 wt%). The temperature range and immersion time for this solution are 120 to 140°F and 10 min, respectively.

Nitric-copper sulfate mixes

This solution is an alternative for free machining 200, 300, and 400 series alloys. It contains HNO3 (1 to 12 vol%) plus CuSO4·5H2O (4 wt%). Immersion temperature range and time are 120 to 140°F and 10 min, respectively.

Citric acid/citrates

Passivation of some alloys with citric acid sodium nitrate mixtures has been commercialized over the past ten years or so, but to date, it has not seen a high level of acceptance. One client that investigated the process declined its use due to long immersion times (60+ min) and poor corrosion resistance performance.

5 to 10 wt% ammonium citrate is also mentioned as an alternative to nitric acid-based passivating solutions. The processing time range is 10 to 60 min, but ammonium ions pose a wastewater treatment headache.

Other acids

Sometimes, stainless steel requires passivation after assembly into a complex structure containing other metals. In other cases, the part is too massive to fit in a tank. Solutions have been developed to field passivate such problem parts.

- Alternate 1. A solution containing hydroxyacetic acid (2 wt%) and formic acid (1 wt%) plus proprietary inhibitors at 200°F for up to 6 hr can be used when stainless steel parts are mated to steel parts.

- Alternate 2. An ammonia-neutralized solution of EDTA containing proprietary inhibitors at 250°F for 6 hr, followed by a hot-water rinse and a dip in a solution of 10 ppm ammonium hydroxide plus 100 ppm hydrazine, can also be used for stainless steel/iron combinations.

For all solutions indicated, temperature, immersion time, and chemical composition of the passivating solution are the three main operational parameters that must be in good control. Just because a range of temperature and time are given does not mean that the solution may fluctuate between those values during use. In general, once an operating temperature is chosen, it should be controlled within 2°F. Once an operational time is chosen, it should not fluctuate by more than about 10%.

The pH of the final rinse should be 6 to 8, preferably 6.5 to 7.5.

Before any large number of parts is processed, it is always a good idea to pre-test a sample or a section of a large part to make sure the chosen process chemistry and operating conditions will succeed and not aggressively etch the parts (all too often, a result of rushing to the production line).

QC/QA

A common test employed to verify proper passivation of stainless steel is ASTM B177 (Salt Fog), with some specifications for medical devices requiring 336 hr of exposure with no rust spots visible.

Other QA/QC tests described in ASTM B380 include:

- Humidity: The part is exposed to 95 to 100% RH at 100 to 115°F (38 to 46°C) per ASTM D2247 for 24 hr. No visible signs of corrosion are allowed.

- Copper sulfate spot test (aka, Preece Test): This test does not work well on some 400 series stainless steels, especially those containing less than 16% chromium. On 200 or 300 series stainless steel, a drop of copper sulfate solution (4 g of copper sulfate pentahydrate plus 1 mL concentrated sulfuric acid in 250 mL of DI water) will galvanically displace free iron from the surface with metallic copper, producing a copper colored stain that does not readily wipe off. The solution has a shelf life of about two weeks. Unless conducted on a daily basis, it is best to make a new solution each time you test. For surgical and dental instruments made of hardened martensitic stainless steels, ASTM recommends an alternate copper sulfate solution be used. This mix contains 5.4 mL sulfuric acid and 4 g of copper sulfate in 90 mL of DI water. If the copper deposited from this solution wipes off, the part passes the inspection.

- Solvent ring test: ASTM 380 describes this test as one to verify the “cleanliness” of the treated stainless steel. A drop of high-purity solvent is applied to the test surface and allowed to dry. If the surface contains soluble residuals, then the solvent will dissolve them and re-deposit them as a “ring” as it evaporates. A black-light may aid in the detection of the residue. The solvent is pre-tested for a “blank” by evaporating a drop on a glass slide.

- Ferroxyl test: This is a classic test for the presence of free iron. A solution of potassium ferricyanide is made (3 wt% salts, plus 3 wt% nitric acid plus 94 wt% water). A drop of this solution will turn blue in the presence of free iron within a few seconds (usually less than 15).

- Obviously, any parts that have been tested using the copper sulfate or Ferroxyl test need to be re-processed through the passivation line, especially if they are to go into the medical or food industry (ASTM and some specifications discourage the use of these tests for such parts).

Frank Altmayer is a Master Surface Finisher and an AESF Fellow who is the technical education director of the AESF Foundation and NASF. He owned Scientific Control Laboratories from 1986 to 2007 and has over 50 years of experience in metal finishing. He was the recipient of the AESF Past Presidents Award, NAMF Award of Special Recognition, AESF Leadership Award, AESF Fellowship Award, Chicago Branch AESF Geldzahler Service Award, and NASF Award of Special Recognition.