Electroplating often requires a considerable amount of space and human resources.

Using a smart profile sensor from Baumer, the Swiss automation company Roth Technik has now developed a fully automatic system for plating racks.

At Collini’s Swiss site in Dübendorf, near Zurich, space is certainly at a premium. Boxes containing small metal parts are stacked to the ceiling in a narrow niche. There is barely enough space to maneuver a single pallet between the wall and liquid tanks. Behind this assembly, there are rows of tightly packed electroplating tanks.

Watch the video

That is the why the company, which specializes in surface coatings, was looking for a space-saving solution that would give it a fast and reliable way of hanging small parts on racks for the electroplating bath. The conventional method of loading the racks by hand requires a lot of space and human resources because several racks need to be loaded at the same time.

New Coating System with Automated Loading

“For that reason, we wanted to switch to a new coating system with automated loading,” says Marco Fuchs, Head of Product Engineering at Collini. Since a system of this type had yet to be created, however, he embarked on a search for companies that would have the pioneering spirit to take up the challenge.

“For that reason, we wanted to switch to a new coating system with automated loading,” says Marco Fuchs, Head of Product Engineering at Collini. Since a system of this type had yet to be created, however, he embarked on a search for companies that would have the pioneering spirit to take up the challenge.

Fuchs found the right partner in Swiss automation company Roth Technik, which in turn relies on smart sensor solutions from Baumer for its projects. A specialist in smart, bespoke automation solutions, Roth Technik worked closely with its customer Collini to develop a fully automatic and compact loading line.

At the heart of the line are four robots that automatically load parts onto the empty hooks on the racks. The biggest challenge for the system to overcome was the fact that no two racks are the same: The hook positions are not located exactly in the same place on the welded racks every time – and some hooks may be bent or missing entirely. This isn’t a problem for human personnel to deal with, but it very much is for robots that require precise positioning data. The enormous variety and high throughput of parts presented two more challenges.

Robots Guided Efficiently by Smart Baumer Sensor

So how did the Roth Technik team solve the problem of rack position inaccuracy, enabling the robots to learn the exact positions of the hooks for each rack?

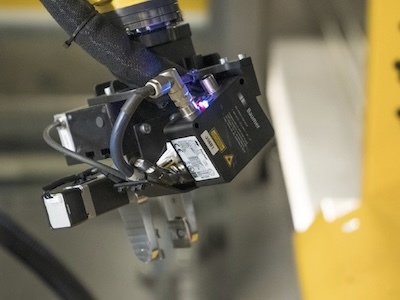

The development team found a simple yet effective solution in the compact OXM200 profile sensor from Baumer. Mounted on the robot arm, it detects the exact position of each individual hook as it moves down the rack and reports this back to the robot control. With the help of a camera, the robot then picks up one part after the other from the separating carousel and hangs it on a hook.

The robot uses the position coordinates previously collected by the profile sensor to finely adjust the position of the part. This method is what enables the smart profile sensor to guide the robot precisely and quickly on the electroplating rack.

The process might sound simple, but in order to work it requires the profile sensor to deliver outstanding performance.

“We had to install sensor technology that detects and precisely measures very thin hooks – not just in a two-dimensional space, but in a three-dimensional one too,” says Markus Roth, CEO of Roth Technik.

This means that the sensor must be able to detect small objects (i.e., objects with a small minimum size) and feature a large field of view so that it can scan several hooks at the same time. And all this with pinpoint accuracy to prevent any subsequent errors.

Baumer Profile Sensor More Suitable than Cameras

Marco Fuchs, left, is Head of Product Engineering at Collini.To begin with, Markus Roth’s team had tested various solutions with camera-based systems and other laser-based scanners.

Marco Fuchs, left, is Head of Product Engineering at Collini.To begin with, Markus Roth’s team had tested various solutions with camera-based systems and other laser-based scanners.

“In the end, we went with the profile sensor from Baumer because it was the best solution for our strict requirements regarding accuracy, compact design, and ability to detect objects,” Roth says.

The compact OXM200 reliably detects the thin hooks and is still able to scan several hook positions at the same time. Using the control, it then decides whether or not to load the hook. The OXM200 offers another major advantage: Thanks to powerful, integrated measuring tools, the sensor outputs the measured values for the X and Z coordinates directly in mm, significantly reducing the number of calculations in the control.

“This requires less integration work on the software side and enables us to get the project up and running faster as a result,” says Roth.

Thanks to Power over Ethernet (PoE), a single cable is all that is needed to connect the sensor to the control and supply it with power – an important detail when it comes to mounting the sensor on a mobile robot arm.

Further time savings are achieved by scanning the hook positions only once when the rack is inserted. What’s more, the control stores all the hook positions so that the racks do not have to be scanned each time.

“The two robot cells enable a throughput of 15 million parts per year,” Roth says.

Roland Thum, an expert in advanced sensors at Baumer, joined the technical discussions that guided the Roth team in selecting the right sensor for this pioneering application.

“Markus Roth asked me for reliable sensor technology that would be easy to integrate with a view to fine robot positioning,” he says. “I immediately thought of the OXM200 smart profile sensor, which is ideal for tasks like these – it’s compact and lightweight, and offers a variety of interfaces along with simple cabling. As a result, it’s very easy to integrate onto robot arms.”

Robot Cell Solves Space and HR issues

After a test run, the system was put into operation in July 2022. It achieves the required cycle times and is able to load the defined range of parts. This automation solution has solved both the space and HR issues at Collini’s electroplating workshop in Dübendorf – and has increased profitability to boot.

“The two robot cells enable us to make the best use of our limited space and reduce our personnel costs at the same time,” Fuchs says. “I am very proud that we were able to solve this tricky problem. To crack tough cases like these, you need a highly motivated team and top-quality components.”

Visit www.baumer.com/c/41517