Several years ago, the prices for nickel anodes and related plating salts rose steeply.

Since then, the prices have remained significantly high, resulting in platers working their costs into pricing finished parts.

At times during the nickel plating operation, problems occur that require a specific type of corrective action. Equipment malfunction or breakdowns are sudden problems that affect the plating cycle. These are examples of unforeseen problems that happen even with the implementation of good maintenance practices. Unfortunately, there are problems that can be avoided or significantly minimized when they occur. Poor maintenance or lack of standard control becomes expensive mistakes can be significantly minimized. When such problems occur, they typically result in nickel plating rejects, production drop or shutdown, failure to meet delivery dates and other unfortunate situations. The bottom line is the inability to ship and bill orders.

In effect, nickel plating rejects may be due to a myriad of collective problems, not just one.

- Cleaning and Activation

- Rinsing

- Plated deposits prior to nickel

- Chemical Imbalance of the nickel bath

- Organic or metallic contamination of the nickel bath

- Post-nickel plating operation

These and other potential problems highlight the need to implement best practices in the operation and chemical analysis with proper maintenance additions. Reject parts are either scrapped or stripped to be reworked. The finisher thus has additional operating costs. If parts are scrapped, these are typically paid for. Stripping and rework may triple the in-house processing cost compared to raw parts. In either situation, the customer’s trust and continued business may be affected. Process suppliers of proprietary nickel additives such as brighteners have typically built a comprehensive working knowledge of the systems they sell and service. Field service technicians and lab support staff can offer quick, effective responses to most service needs and assist in implementing corrective action.

Many shops have an active in-house lab and equipment staff to maintain a schedule of chemical, mechanical, and electrical maintenance. Customers who visit to audit their plating shop supplier appreciate the continued overall maintenance of the quality of their parts. Some items for consideration as regards the nickel plating tank are listed.

Anodes

S-type, sulfur-containing anodes are used most prevalently in bright nickel plating. R-type is also used. The S-type is more conductive, requiring less voltage for plating. A black film of insoluble sulfur forms on the S anode skin during plating.

Especially with the cost of nickel, the R-type, sulfur-free, might be purchased at a price cheaper than the S-type. Sometimes this results in a mild panic when the plating voltage has to be raised to meet the desired current densities, as the nickel degradation is not as efficient as in the s type. Be advised beforehand as to what occurs when a switch is made from S to R anodes.

Whichever anode type is purchased, first request a certified analysis for the material. Only the highest purity should be used, typically over 99.5%, as nickel. Caveat emptor! Let the buyer beware.

When filling the anode baskets, take care not to add even one other plating bath anode inadvertently. I have seen this happen a few times. Just one zinc ball in a 1,000-gallon nickel bath results in catastrophic problems. There is a maintenance problem that can occur if not checked for. Through plating use, the anodes tend to settle, sometimes forming empty pockets. This can result in polarization and a lack of localized plating on parts facing the blank zones.

When not in use, a bar or rod should be lowered and raised in the basket, filling the voids, eliminating this problem.

Anode Bags

It is good practice to change anode bags when there are large additions of anodes to be made into the baskets. Remove the baskets, empty the remaining anodes, and wash them and the baskets. The bags should be pre-washed in a solution of 5% sulfuric acid containing about 0.1% of the nickel-wetting agent. This removes any organic sizing-related materials from the fabric, eliminating organic contamination in the nickel bath.

Dynel bags are recommended. Double bagging can also be used. The inner bag is Canton flannel, and the outer bag is Dynel. Maintenance replacement of bags is important. Aged anode bags will tend to plug, resulting in polarization and deposit pitting. During production use, the bags may also tear or rip. Including anode bags in the standard maintenance, list should greatly minimize any of the described related problems.

Metallic Contamination

The most common metallic contaminants that can be dummy-electrolyzed out of solution are copper and zinc. Gray to black, streaked deposits in the low current density areas indicates this type of metallic contamination. For minimal-to-slight deposit streaks, proprietary purifiers added to the bath effectively whiten the deposit. This permits continued, uninterrupted production use until the bath can be shut down for proper dummy-electrolyzing. The purifier is not a cure, just a temporary fix until proper dummying can be conducted. For severe contamination, typically above 25 ppm of copper or zinc, immediate dummying is required.

For optimum dummying, it is best to lower the bath pH below 3.5. Use scrap parts, corrugated sheet metal, or expanded metal (focus on a significantly low current density area for the dummy). First, plate a thin, uniform deposit of nickel over the entire dummy. Then, lower the current density to plate out the metallic contaminant, preferably aggressively. Thorough agitation, either air or mechanical, is very beneficial. For zinc, the current density would be 4 A/ft2 for less than 50 ppm of zinc and 2 A/ft2 for levels above 50 ppm of zinc. For all levels of copper contamination, dummy at 2 A/ft2.

Every 60 to 90 minutes, raise the current density for 15 minutes to the range used for nickel plating. Stop dummying, raise the dummy, and observe the deposit appearance in the low current densities. If it is black or gray, continue the dummying procedure. Once the low current densities confirm the preferential deposition of white nickel, the dummy purification can be stopped. The bath will then have been sufficiently purified.

The problem leading to the need for a dummy must be addressed. The main cause is due to parts dropping off racks or, more commonly, out of plating barrels. Be certain that racks and barrels are in good service and the correct ones are used. Prior deposition of copper should sufficiently seal the base metal surface. The following example should illustrate how important this is.

Consider a situation where one pound of zinc parts drops into a 500-gal nickel bath. 50% of the parts dissolve, resulting in 120 ppm of zinc contamination. It can happen that quickly. Therefore, regularly checking for and removing dropped parts is very important. If suited to the particular operation, fasten a net across the tank bottom to more easily retrieve the parts.

There is another maintenance procedure, if space permits, that could be set up. This would be a continuous dummy cell, operating whenever the plating bath is running. The plating solution pumps to the purification tank, where the solution is dummied, then pumped through a carbon filter, and returned to the plating tank. For a 500-gal nickel bath, at least a 50-gal purification cell, dummying at 2 A/ft2, should be sufficient.

Organic Contamination

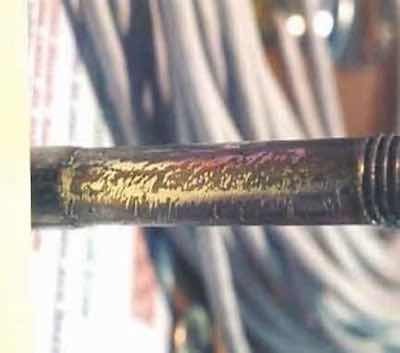

Burnt and dark nickel deposit.Deposit brittleness, clouds, hazes, pitting, and overall dullness are usual indications of organic contamination. Brightener breakdown products, drag-in of trace cleaner rinses, residual oils, and grease on parts will gradually build up with time in the plating bath. This contaminant buildup problem has become more prevalent with the extensive application of closed looping. It can be greatly minimized by continuous carbon filtration. Approximately two to four oz. of carbon in the filter per 100 gal of plating solution volume should be sufficient to remove light to moderate amounts of organic contamination.

Burnt and dark nickel deposit.Deposit brittleness, clouds, hazes, pitting, and overall dullness are usual indications of organic contamination. Brightener breakdown products, drag-in of trace cleaner rinses, residual oils, and grease on parts will gradually build up with time in the plating bath. This contaminant buildup problem has become more prevalent with the extensive application of closed looping. It can be greatly minimized by continuous carbon filtration. Approximately two to four oz. of carbon in the filter per 100 gal of plating solution volume should be sufficient to remove light to moderate amounts of organic contamination.

Diatomaceous earth is a suggested filter media. Manufacturers of specific filtration equipment typically recommend how to charge their units with carbon, equipment maintenance, and re-charging. The important item is not to let a fresh charge of carbon go on without any change. I have seen return flows from the filter greatly diminished due to the extensive clogging of the filter medium. Without routine maintenance and changing of the carbon pack, there is little to no benefit derived from carbon filtration.

In the event of severe organic contamination, a batch treatment with a heavier dosage of carbon would be required, along with the possible addition of an oxidizing agent, such as hydrogen peroxide or potassium permanganate. The appropriate amounts of purifying additives should be first determined in the lab based on the particular problem and effect of bench scale treatment.

Nickel blister.Some general plating defects with possible sources of the problem are:

Nickel blister.Some general plating defects with possible sources of the problem are:

- Poor Adhesion: Inadequate cleaning, low acid in the preplate activator, pH of bright nickel out of range, stressed nickel deposit (metallic contamination or excess brightener).

- Laminated or Hazy Deposit: current interruption during the plating cycle where nickel peels off nickel, highly stressed deposit, organic & or iron contamination, pH out of range.

- Stressed Deposit: iron contamination, brighteners out of balance or in excess, organic contamination, pH out of range, high chloride.

- Deposit Pitting: bath has high surface tension (requires the addition of wetting agent to lower surface tension), nickel solution contaminated with oil and or grease, insoluble particles in bath, inadequate agitation, low bath temperature.

- High Current Density Burn: low concentration of nickel metal salts, low proprietary Carrier additive, pH out of range, low bath temperature.

- Dark Sections of Deposit: High brightener concentration.

- Streaky Deposit: brightener imbalance, pH out of range, inadequate agitation, low wetting agent.

- Rough Deposit: insoluble particles, poor condition of anode bags, smut on steel, excess boric acid, low bath temperature.

- No Plating: Electrical and or rectifier problem.

A nickel bath, especially in these expensive economic times, is not worth gambling on. It is better to take the conservative approach and maintain it properly, adhering to a good service schedule.

Stephen F. Rudy, CEF, is president of Chem Analytic and has written extensively about the finishing industry. Visit www.chemanalytic.com or call him at 917-604-5001.