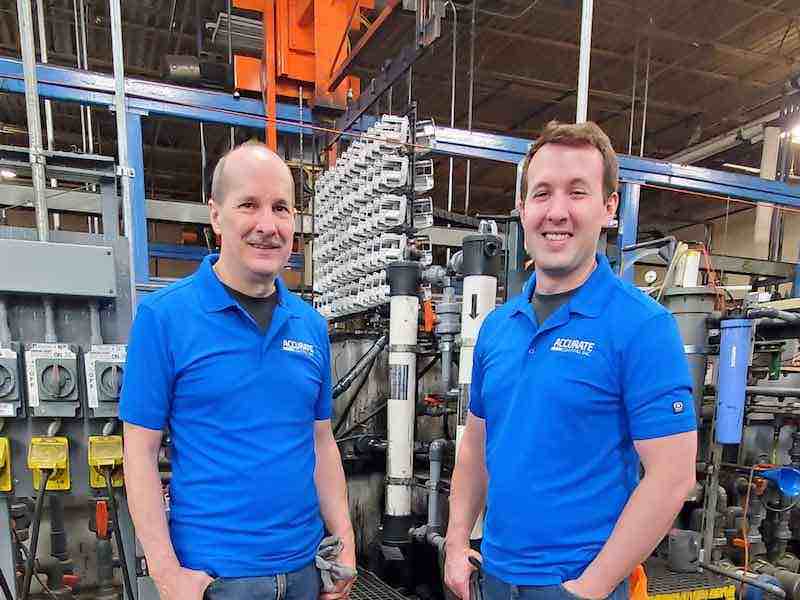

When you take a mechanical engineer and an electrical controls engineer and ask them to design a coating operation, the result just might be a tad impressive when it comes to efficiencies.

That is the case with Accurate Coating in Grand Rapids, Michigan, where two former Keeler Brass engineers took a surplus plating line in 2006 and morphed it into a sophisticated electrocoating operation that is completely automated.

Couple all of that with specializing in finishing new lightweight metal substrates — including magnesium, aluminum, and specialty steel — and the operation might turn a few OEM heads.

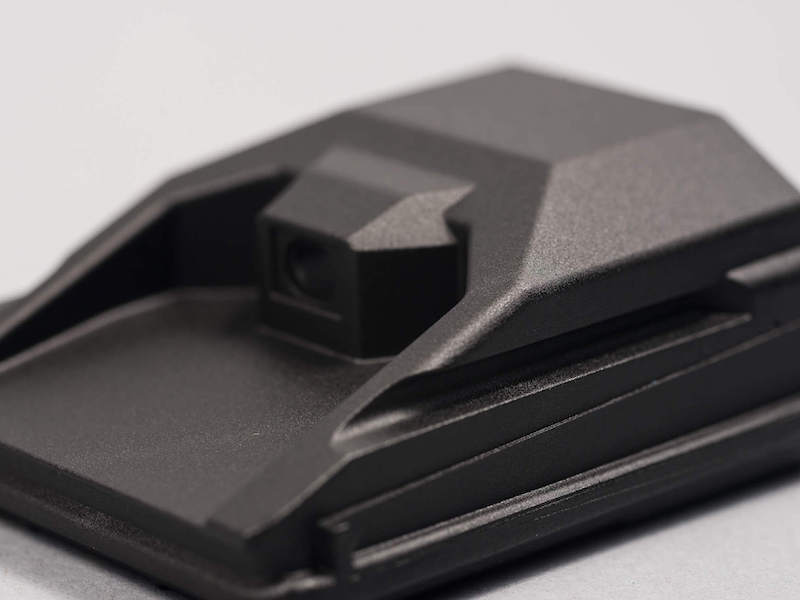

Matte Black Ecoat Finish

Accurate Coatings took a surplus plating line in 2006 and morphed it into a sophisticated electrocoating operation that is completely automated.Tom Mrock, finishing manager at die-caster Chicago White Metal, is one who is impressed by the matte black ecoat finish Accurate Coatings repeatedly turns out on what are often hard-to-coat substrates.

Accurate Coatings took a surplus plating line in 2006 and morphed it into a sophisticated electrocoating operation that is completely automated.Tom Mrock, finishing manager at die-caster Chicago White Metal, is one who is impressed by the matte black ecoat finish Accurate Coatings repeatedly turns out on what are often hard-to-coat substrates.

“What Accurate does with these parts is simply amazing,” says Mrock, who has sent parts to Accurate Coatings for several years. “When you see it, you are blown away by it. And when you see how they do it with robotics and automation, you come away even more impressed.”

General Manager and part-owner Dave Kasper helped start Accurate Coatings in 2006 when he and three other partners took a plating line that was used by their former employer at Keeler Brass and converted it into an ecoat line.

“We laid it all out as a multi-functioning ecoat machine,” Kasper says. “It’s a random-access hoist program, so we can run everything simultaneously, and we have about 99 different menus that we can run at the same time, although we only run 16 bars right now.”

Keeler Brass was founded in 1893 and grew to specialize in manufacturing furniture trim and brass parts for Ford’s Model-T cars. In the 1980s, they were known as the largest manufacturer of hardware for North America’s furniture industry but lost a large share of the market when many companies moved their work overseas.

“We automated everything at Keeler for more than 20 years while trying to keep China at bay,” Kasper says. “When customers started building their furniture in China, that was the kiss of death.”

Converting Plating Line to Ecoat

Fortunately, Kasper and his partners had installed an ecoat line at Keeler and gained enough experience to realize that there was a demand for coating parts, including die casts. When the opportunity arose for the partners to buy a plating line from Keeler for “pennies on the dollars,” Kasper says they jumped at the chance to branch out on their own.

Fortunately, Kasper and his partners had installed an ecoat line at Keeler and gained enough experience to realize that there was a demand for coating parts, including die casts. When the opportunity arose for the partners to buy a plating line from Keeler for “pennies on the dollars,” Kasper says they jumped at the chance to branch out on their own.

“We saw how ecoat was being used on higher-end products,” says Kasper, who had already left Keeler to work in finishing equipment sales. “I got a call from a few people still there who asked if I wanted to help them start an ecoat company, and we jumped on it.”

Unfortunately, Kasper and his partners were just getting Accurate Coatings off the ground when the recession of 2008 hit, which slowed things down a bit.

“We were all engineers, and the notion that if you build it, they will come wasn’t exactly true,” he says. “It was rough going for a while, but we steadily built the customer base over the years to get to where we are now.”

Where they stand now is as one of the more unique ecoaters in North America, having carved a niche in coating magnesium and aluminum die-cast parts for the automotive, defense, firearms, healthcare, recreational, and technology products.

With programs as large as 2 million parts a year, Accurate Coating has mastered the art of applying a matte black polyurethane ecoat, one which grabbed the eye of many OEMs, including Chicago White Metal.

“They do some unbelievable stuff for us,” Mrock says. “We’ve been working with them for a few years, and I am always amazed at their ability and knowledge. And that matte black has a very sexy look to it.”

Polyurethane Finish with 2%-5% Gloss

Accurate Coating uses a polyurethane ecoat formulated by LVH Coatings from the UK and distributed through ClearClad Coatings of Harvey, Illinois. The matte finish has just 2%-5% gloss and excellent QUV performance with a controlled thickness between 15-30 microns. Nano-ceramic matting agent gives it a 4H-5H coating hardness.

Accurate Coating uses a polyurethane ecoat formulated by LVH Coatings from the UK and distributed through ClearClad Coatings of Harvey, Illinois. The matte finish has just 2%-5% gloss and excellent QUV performance with a controlled thickness between 15-30 microns. Nano-ceramic matting agent gives it a 4H-5H coating hardness.

Kasper says the facility added PPG’s Powercron 6000CX black epoxy pursuing demand from existing aluminum and magnesium customers that weren’t happy with traditional steel ecoat shops. “A lot of people have trouble with magnesium running on a line; it’s often detrimental to operating a steel-focused line as some say it poisons the process. Accurate was initially reluctant to enter the space against so many well-established and effective ecoat shops, but it became a tremendous win for the company. In the first year of running epoxy ecoat on light metal parts alone, epoxy coated parts grew to more than half of total sales.

Accurate Coating has become a major magnesium epoxy ecoater in North America because of its expertise in finishing the metal. Kasper says the reactivity of the metal in a liquid process causes it to start to bubble and fizzle, and so it takes some know-how to work the magnesium in a submerged coating bath. He adds many of their customer relationships have been hard-fought - one tough project at a time. Return business of key diecasters and thixo molders, as well as positive word of mouth, continue to attract OEMs and engineers seeking a solution to their problems.

“It’s very much a niche process,” he says. “Being a self-format where we coat each bar one at a time, we can make the necessary adjustments and custom-tune our voltage and current profiles to exactly what we need for the part.”

Likewise, Accurate Coating has been able to master the coating of die castings, too, which some finishers find too finicky to work with because of the often porous surfaces and manufacturing biproducts. Die lubes, machining lubricants, and residuals from the casting process often get left on the surface, and the preparation of the part is the key to quality. Understanding how far pretreatment chemistry can clean and where you need mechanical finishing processes to help is critical. “We have really built a lot of institutional knowledge here on vibratory, blasting, polishing, and sanding and how that complements the ecoat process,” Kasper says.

“You can coat the die-cast, but those contaminants will come back out and will greet you in the oven,” Kasper says.

Alloying Effect Plays Role in Die Casts

Alex Kasper, the operations manager at Accurate Coatings and Dave’s son, says the alloying effect with die casts plays a role in how well the part is coated to meet specifications.

Alex Kasper, the operations manager at Accurate Coatings and Dave’s son, says the alloying effect with die casts plays a role in how well the part is coated to meet specifications.

“They may try to anodize or use electroless nickel in the magnesium and aluminum world, but they often find very uneven finishes,” Alex says. “That is what sends the die casters in search of alternatives such as powder coat and ecoat.”

But powder coating doesn’t always meet the needed tolerances that are required, Alex says, and that is where having a skilled ecoating operation available comes in handy to get a program or trouble part into production.

In fact, about 20% of the parts Accurate Coating ecoats get sent out to be powder coated for a final finish. And with many die-cast parts made of aluminum and magnesium, that is where the Kaspers say they have carved out their niche in the coatings industry.

“The customers with those substrates who are constrained by casting intricacies present some of the best opportunities to sell ecoat,” Alex says.

Aside from a smaller customer near their Grand Rapids plant, Accurate Coatings’ closest customer is roughly 150 miles away from them. Most of their customers are within a four-state range in the Midwest.

“We do a lot of business with customers in the Midwest, and even some on the coasts as far as New Hampshire or California and Washington,” Alex says. “We’re still a small shop; we are not a multinational. We have 14 people working here, and we keep very busy.”

From Electronics to Recreational Lighting to Consumer Goods

The parts range from electronics to recreational lighting to a lot of consumer goods. And Accurate Coating gets a steady groove of new customers calling on them who have just discovered the ecoat process.

The parts range from electronics to recreational lighting to a lot of consumer goods. And Accurate Coating gets a steady groove of new customers calling on them who have just discovered the ecoat process.

“It’s amazing that ecoat has been around since the 1970s, and there are still a lot of manufacturers who don’t know what it is or how to use the finish on their parts,” Alex says.

As any good engineer would, Dave says he is looking at ways to speed up the coating line without sacrificing quality, especially since they have been part of a recent contract project with die caster Dynacast, which is helping to build a theater in Las Vegas.

Dynacast is supplying more than 1.5 million architectural lighting heat sinks — roughly the size of a hockey puck — each small heatsink will act as a pixel of the screen being built around the exterior of the spherical building.

Accurate Coating started the project in late 2021 and has been churning out ecoated parts each month since, with the completion scheduled for later in July.

“When you have a large job like that, you look for ways to speed things up anywhere you can,” Dave says.

Visit http://accuratecoatinginc.com and http://www.cwmtl.com