Progressively tighter cleanliness specifications of high-precision manufactured parts require their manufacturers to optimize the process parameters of part cleaning systems.

Michael Beeks, Jeff Beard, and Chris Jones are with Brulin.Aqueous cleaning in immersion or “soak” equipment is widely used for this kind of part degreasing. The addition of tank agitation to this equipment is an effective way to clean high-value parts and offers efficiency, reduces cycle times, and improves the overall degreasing process.

Michael Beeks, Jeff Beard, and Chris Jones are with Brulin.Aqueous cleaning in immersion or “soak” equipment is widely used for this kind of part degreasing. The addition of tank agitation to this equipment is an effective way to clean high-value parts and offers efficiency, reduces cycle times, and improves the overall degreasing process.

Air sparging as a form of agitation can damage the cleaning solution, prevent optimal cleanliness and lead to excessive foaming. Under surface turbulation using eductors is an alternate form of tank agitation and the most effective way to ensure a clean part while reducing processing time and extending bath life.

Aqueous Degreasing With Agitation

Precision degreasing of sophisticated parts is an integral part of today’s high-reliability manufacturing process. Most high-value parts can be cleaned effectively in a well-specified aqueous cleaning process, though adjustment of the process might be necessary as cleaning requirements, parts, or soils change.

Manufacturers are also looking for ways to reduce cycle times and improve the overall degreasing process. All of these goals can be achieved in many cases by optimizing the washing process parameters. Tank agitation is one way to enhance the process.

In an aqueous degreasing tank, a stagnant boundary layer with soil-saturated surfactants forms next to the part surface to be cleaned. This layer acts as a barrier between the part surface and the bulk of the cleaning liquid, which reduces the cleaning action in the tank. Creating agitation in the tank displaces this layer and allows the fresh solution to flow to the part’s surface, which greatly enhances the rate of cleaning.

Air Sparging

Figure 1: Soak Tank Air SpargeOne common method of tank agitation discouraged by Brulin is the use of air sparging. Air sparging is accomplished by pumping air through the cleaning tank, often through a pipe with holes drilled to release air bubbles into the tank.

Figure 1: Soak Tank Air SpargeOne common method of tank agitation discouraged by Brulin is the use of air sparging. Air sparging is accomplished by pumping air through the cleaning tank, often through a pipe with holes drilled to release air bubbles into the tank.

By introducing air into the tank, several problems may occur:

- Air brings CO2into the tank, which subsequently forms carbonic acid. This acid reacts with the alkaline components of the aqueous solution reducing cleaning effectiveness.

- This acid formation also artificially reduces the bath life of the aqueous solution by reducing its pH, resulting in the loss of corrosion inhibitors.

- Oil may be introduced into the tank via the input air being contaminated by the compressor or the atmosphere.

- Bubbles are not an effective method of agitation to achieve thorough tank mixing.

- Air or vapor bubbles can form on the underside of some parts when submerged in liquid. Where the surface is in contact with a bubble, contact with the process liquid is inhibited. As a result, no plating/coating/ cleaning occurs at those locations. Effective agitation such as turbulation can correct this by creating currents of liquid which can physically push the bubbles away from those locations.

- The airstream also introduces oxygen into the tank, which could lead to oxidation corrosion.

- Air introduction can cause excessive foaming of detergents designed specifically for soak tank degreasing (i.e., without de-foaming capability). Foam not only causes issues in the soak tank but the foam also is typically dragged into the first rinse causing contamination of the rinse.

The problems caused by air sparging are counter to the expectations of any facility that degreases parts.

In short, air sparging:

- Is an inefficient method of agitation.

- Damages the integrity of the cleaning solution.

- Leads to premature failure of corrosion inhibition.

- May prevent the cleaning solution from reaching the underside of some parts.

- May lead to excessive foaming and excessive drag out of foam into the rinse tank.

Tank Agitation

Figure 2: Drag out of detergent into Rinse 1We recommend tank agitation using some method other than air sparging.

Figure 2: Drag out of detergent into Rinse 1We recommend tank agitation using some method other than air sparging.

Tank agitation creates movement of the solution to present the fresh detergent solution to the surface of parts, optimizing the effectiveness of the detergent. It creates mechanical action through direct impingement of the cleaning solution on the part surface, further improving the soil removal. As a best practice, avoid the introduction of air or agitation at the air-liquid interface, which would create all the problems described above.

Under Surface Turbulation

For best results, we recommend under surface turbulation, which uses eductors.

The plume of liquid coming from the eductor passes over the surface of the part and provides a mechanical scrubbing action which enhances the cleaning effect. This cleaning action can be varied by the number of eductors, pump size, and spray pressure.

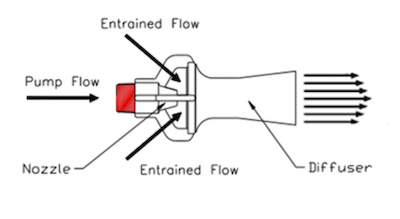

The nozzle generates a high-velocity fluid jet to entrain the liquid surrounding the eductor. The fluid in the nozzle jet and the entrained liquid are forced through a diffuser where the high throughput velocity creates a turbulent flow. The turbulence is very effective at mixing the fluid from the nozzle with the entrained liquid while avoiding agitation at the air-liquid interface.

The advantage of an eductor is that the discharge plume is much broader than the jet from a solid stream nozzle of equivalent energy.

Eductors enable small pumps to efficiently circulate large volumes of tank solution. Each eductor will circulate a tank volume equal to four to five times the solution volume pumped.

The eductors also suspend solids and sweep debris or sludge toward a filter intake for more effective filtration. This greatly reduces particulate from settling on the tank bottom, which causes maintenance issues.

Eductors mix and agitate without introducing foreign matter, reducing solution temperature, or creating liquid layers. Eductors are clog-resistant, have no moving parts, and don’t wear out.

Using an agitation rate equivalent to 50X turnover/ hour, a manufacturer may expect the required time to remove the surface contamination to be reduced by about 33%. Parts with blind holes utilizing directed eductor solution agitation may also expect to see a significant reduction in cleaning time of up to 50%1.

Eductors are a relatively inexpensive way to greatly enhance the quality of the chemical action of the cleaning solution and add a greatly enhanced mechanical component to the cleaning process.

Benefits of Under Surface Turbulation:

- Reduced processing time

- Greater bath life

- Less external contamination

- Less oxidation corrosion potential

Other Effective Methods of Tank Agitation

Illustration courtesy of BexThere are options for tank agitation that improve on the limitations of a stagnant soak tank without all the drawbacks of air sparging.

Illustration courtesy of BexThere are options for tank agitation that improve on the limitations of a stagnant soak tank without all the drawbacks of air sparging.

Ultrasonics: Sound waves create small bubbles which implode on the part surface, scrubbing debris away. The implosion releases high energy, which creates both heat and power to assist in the scrubbing action. The ultrasonic frequency determines the cleaning power. Lower frequencies are more powerful and less directed. Higher frequencies are less powerful but can be directed to the part. This is most effective generally in smaller tanks due to the high cost of the equipment required.

Stroke: Up and Down movement of the parts within the tank solution. Typically the parts are racked on a platform that moves the parts through the tank. This action keeps fresh cleaning solution on the part surface as well as moves solution to keep it well circulated within the tank. Stroke helps to carry soils away from the part surface.

Tumbling: This type of agitation is used in parts with shapes that can entrap the solution within cavities, such as small parts with blind holes, cavities, and cupping. The parts are racked in a basket or fixture that rotates within the cleaning solution. In many applications, stroke and tumbling are utilized within the same process.

Recirculation: A pumping of the solution from one end of the tank to the other to create a constant, usually low-speed, fluid flow. A more effective recirculation would be accomplished using eductors.

Agitator: Cleaning solution movement within the tank is accomplished using a propeller or other turbine agitator. This is the most generic type of agitation and would be the least effective method other than air. It does provide solution movement, which can help with cleaning; however, this method does not give any other benefits as described above.

Conclusion

In conclusion, we suggest that a modest investment in cleaning tank modification to eliminate air sparging can provide significant savings in improved part processing, saving both time and money. Request a Health Check of your current system to match the right cleaning chemistry to the needs of your process and also to recommend other ways to optimize your process.

- “Effectively Reducing Cycles Times in Aqueous Cleaning Processes,” Jeffrey Beard and Silvio Pioli, A2Z Metalworker, April/May 2011

Michael Beeks is a Brulin Science Advisor, mbeeks@bhcinc.com; Jeff Beard is Business Development Manager, jbeard@bhcinc.com; and Chris Jones is International Business Manager, cjones@bhcinc.com. Visit brulin.com