When it comes to wastewater treatment systems, bioaugmentation is becoming more common at many finishing operations as limits continue to tighten around nitrogen, phosphorus, and other contaminants.

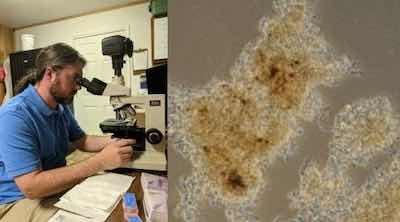

Jeremy MorganBiological removal is used as a “final polish” to achieve permit limits and reduce disposal costs, says Jeremy Morgan, Product Manager of Biological Products at Hubbard-Hall.

Jeremy MorganBiological removal is used as a “final polish” to achieve permit limits and reduce disposal costs, says Jeremy Morgan, Product Manager of Biological Products at Hubbard-Hall.

Previously, Morgan was the Vice President of Technology at BioConversion Technology, which Hubbard-Hall purchased in 2023. The company offers custom blends of specially selected bacterial strains that work under aerobic and anaerobic conditions with no caustics or acids so as not to cause harm to pipes or wastewater equipment.

I recently spoke with Morgan about the intricacies of bioaugmentation to help reinforce and rebuild existing biological treatment systems to help meet stringent discharge permit limits.

Tim Pennington: This is something that's fairly new to me, as I had yet to hear much about biological products in wastewater treatment. Why don't we start off with an overview of biological wastewater treatment and fill in those gaps for people who may need to learn a little about it?

Jeremy Morgan: Rather than conventionally removing pollutants, heavy metals, or that kind of thing from a waste stream using chemistry or physical separation, we're using bacteria to break down those compounds and help remove them from the waste stream. The bacteria grow in a mass, whether in a tank or on a surface, and the waste stream makes contact with the bacteria. They degrade those substances, whether BOD/COD or nutrients like nitrogen or phosphorus, and break those compounds down and remove them from the waste stream.

TP: Most people in the finishing industry would consider removing metals, phosphates, and other contaminants, but do bacteria need to be removed as well? Are those often measured by the local municipalities?

TP: Most people in the finishing industry would consider removing metals, phosphates, and other contaminants, but do bacteria need to be removed as well? Are those often measured by the local municipalities?

JM: Yes. Some pre-treat systems may not be permitted for phosphorus or nitrogen, but that's probably going to change in the future. As regulations get tighter and tighter for those municipalities themselves, that's eventually going to trickle down to the pre-treat systems. So, I would expect that at some point in the future, every pre-treat system will have some kind of nutrient permit for nitrogen and phosphorus.

TP: You mentioned two: nitrous and phosphorus. What can a biological system remove from a wastewater treatment?

JM: The top three things would generally be BOD/COD. That's the primary food source for the bacteria. After that, we will refer to macronutrients, nitrogen, and phosphorus compounds. Nitrogen is usually in the form of ammonia, and phosphorus is in the form of phosphates. After that, there would be a secondary group of nutrients called micronutrients, which are generally trace metals and minerals that help support the bacteria. Now, that being said, I don't want people to be confused. We won't be able to remove hundreds of parts of metals using bacteria. Very high metal levels are inhibitory and toxic to the bacteria. But it works great as a final polish. So, if you have a permit limit that's, say, less than one milligram per liter, the biological systems will tend to do a very nice job of polishing those down to very, very small part per billion levels.

TP: How many finishing shops have something like this?

JM: At the moment, probably only a few shops. I feel that that will continue to grow simply because those nutrient permit limits continue to drop. As local municipalities receive tighter limits on those compounds, they will eventually pass that along to many shops. So, I think that if the shop can't control those values chemically, biological systems will become more of an option for them.

Watch the video

Episode 15: The Power of Biologics Part 3: Training for Microbial Mastery - Video Episodes, Season 2

TP: What types of biological systems are used in the wastewater?

JM: There are several different variations. So, your conventional systems, as you would find at a local municipality, a sewage plant, or conventional activated sludge. In those systems, you basically have a tank or a basin with a very high concentration of bacteria in that system. Regarding concentrations, somewhere in the neighborhood, there are usually three to 5,000 milligrams per liter of suspended solids. And that's just suspended in that tank or basin. Now, other systems, which will probably be a bit easier for most metal finishing shops to use, would be what we refer to as fixed-film systems. So rather than being suspended in a tank or a basin, there are actually surfaces that the bacteria attach themselves to that the waste stream flows over. So that would be things like bio towers or trickling filters or MBBRs, moving bed bioreactors. Those types of systems tend to be a little bit easier to operate. It's probably a lot easier for most metal shops to utilize a fixed film system than a conventional activated sludge system.

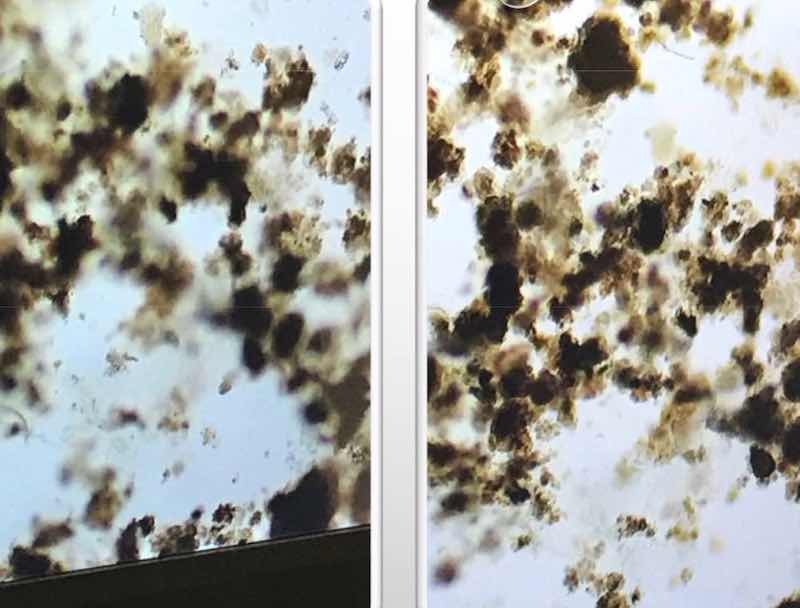

Industrial biological treatment in real time: (L) influent and (R) effluent.TP: Let's discuss the components. I know that many operations are always worried about space and fitting things in. Do we need to buy a lot of equipment?

Industrial biological treatment in real time: (L) influent and (R) effluent.TP: Let's discuss the components. I know that many operations are always worried about space and fitting things in. Do we need to buy a lot of equipment?

JM: The primary component would be a tank or vessel to contain and hold the biomass. That will be very similar footprint-wise, whether it's a conventional activated sludge system where the bacteria is suspended in the wastewater or a fixed film system where the bacteria grows on a surface. So that's number one. You have to have somewhere to hold the bugs.

TP: This would be a new system; this would be a new tank? Would they have an existing tank, or would they probably need to get a new tank?

JM: It depends. It depends. Ideally, it would be a brand-new tank, freshly designed and plumbed to be able to handle the new operation, but I've seen plenty of systems that have repurposed an old tank or an old basin and retrofitted it accordingly. So, it just depends upon the design and the budget for that particular system. The second major component, most systems, will be what we refer to as aerobic, meaning that the bacteria need an oxygen source; they need air. So, you'll need some kind of what we refer to as a blower, basically an air pump device that pumps air into the system, and that's going to be the same again, regardless of whether it's a fixed film system or a conventional system, you have to be able to give those little guys something to breathe. So, you have to have an air source, and those air sources can vary. I've seen some small plants and shops that utilize their existing compressed air system with some adjustments to get enough volume in there. Still, specialty blower devices are designed specifically for wastewater treatment. Now, that being said, generally, the finer the bubbles for the air that can be introduced to the system, the better. You don't want to run a three-eighths-inch tubing down to the bottom of a tank. That's not going to get you enough air in there. So, you need some kind of diffusion device to distribute it. Again, generally, the smaller those bubbles, the more access the bacteria have to the air. So that's the second major component; you must give those guys something to breathe. After that, there are several metrics that you want to pay attention to to make sure that the environment is right for the bacteria to grow and populate and do the removal job that you want them to do. A certain amount of air is in there, called dissolved oxygen, or DO for short. Some specific meters and probes measure the concentration of oxygen in the system. So, that's very critical. pH is also critical; most metal shops will be very comfortable with pH.

TP: It's what they do every day.

JM: Exactly, exactly. That said, for pH, bacteria generally like a neutral pH, so somewhere around 7, and most systems will run somewhere between 7.0 and 8.0. After pH, other things like alkalinity can be very important to monitor. ORP can also be very important to monitor, depending on the components you're trying to break down. So, that third component is going to be your overall measurement devices. Those are critical, along with the air and the components of the tank or basin, to hold. And then lastly, a lot of shops that already have an existing wastewater treatment system are going to be familiar with this too, but the bacteria being a kind of living, breathing biomass, you do have to remove some of those generated solids from the biomass itself. So, you have to be able to separate those solids, and ideally, you want to remove some of those solids every day. Basically, again, using the analogy that it's a living, breathing organism, you can get too much, so you can basically produce too many bacteria for the food sources that are available. So, wasting out some of those solids every day is absolutely critical. So, you need to have a filter press or screen, something like that, or a rotary vacuum drum to remove those solids from the system.

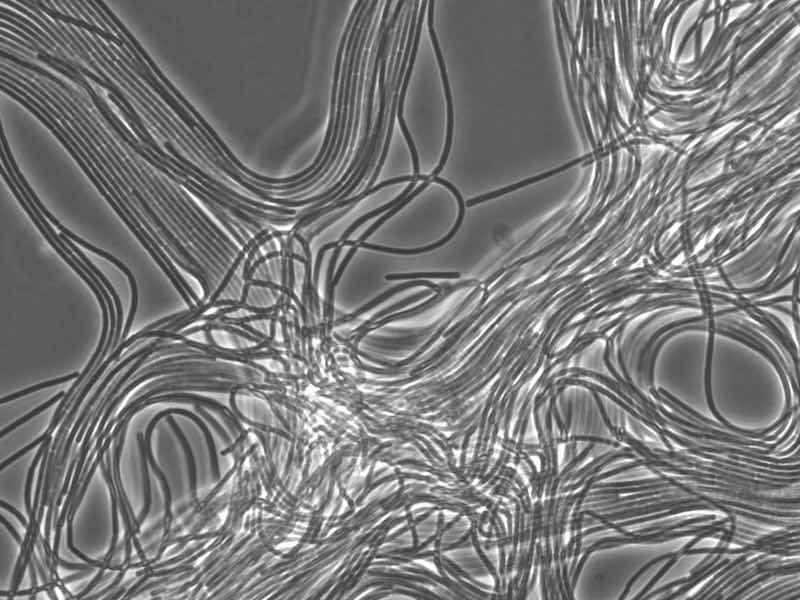

The presence of some filamentous bacteria is beneficial in floc formation to a biomass.TP: You mentioned a few things that must be measured to keep it running well.

The presence of some filamentous bacteria is beneficial in floc formation to a biomass.TP: You mentioned a few things that must be measured to keep it running well.

JM: Obviously, it is pH, which most systems will be comfortable with already. ORP is also a metric that I really like to look at, which kind of goes hand in hand with measuring dissolved oxygen. ORP and DO measurements are kind of similar, but they are a little bit different. Basically, in low oxygen environments, dissolved oxygen measurement isn't very accurate, but ORP is. In addition to that, alkalinity can be a critical value to measure. Suppose the system has to remove a lot of nitrogen or ammonia. In that case, the alkalinity measurement will ... Basically, the removal process for ammonia biologically consumes a lot of alkalinities, so there needs to be enough available alkalinity for the bacteria to remove that ammonia. Those are the major components or metrics to measure, in addition to temperature. Bacteria like to have a consistent temperature bracket where they live, generally between 80 to 95 degrees Fahrenheit. So that's kind of their sweet spot. Once you start getting above 110 Fahrenheit or below 55 degrees Fahrenheit, the environment changes enough that the bacteria tend not to be happy, particularly at those lower temperatures. The whole activity just slows way, way, way down. Temperature can be very important, but those are the basics of measurements, in addition to the amount of biological solids in the system, so you can maintain consistency.

TP: I know many shops try to make their own tanks, racks, and everything else. Would you encourage them to look at doing it themselves, or do they really need to buy a prefabricated system?

JM: In certain circumstances, they can build their system if low levels are removed or just a slight polish. There's nothing wrong with that. But for any new system, I would encourage the end user to contact a system supplier or an engineering firm to be able to design a proper system for them. Yes, it is certainly more expensive to do so, but the return on investment for a properly designed system can really keep them out of trouble and, in the long run, honestly, save them money.

TP: Let's discuss training and operating the system. What should we consider? You need to hire a professional.

JM: A professionally designed system will certainly pay dividends, but there is some specific training that goes along with running a biological wastewater system. It's certainly not necessarily a steep learning curve. Still, it will probably be a bit foreign to most folks if they've never been exposed to a biological system. So, one of the things that I highly encourage anyone who is just starting this form of treatment is to attend some local training classes. Every state usually has one or two entities that provide training for wastewater treatment systems. Most municipalities ... well, I won't say most municipalities, but all municipalities, the operators, are required to be licensed by their governing state. Like any other professional licensing commission or board, there is a professional licensing system, whether you're a doctor or a lawyer. I highly encourage operators to attend some of those training sessions to learn how to operate and be more comfortable with those types of systems. So, that's generally the first thing I would recommend. It's certainly not a requirement, but those training sessions and classes will go a long, long way to understanding how these systems work.

TP: Many wastewater operators talk about contacting their local governing agency and asking about classes and even manuals.

JM: Most local municipalities, particularly if you operate a pretreatment system that discharges to that municipality, are generally more than happy to direct you where to go for additional education or help you out directly. So that's one thing: Don't necessarily be afraid of your local governing body or municipality; they're there to help you out.

Tardigrades, often called water bears or moss piglets, are near-microscopic animals with long, plump bodies and scrunched-up heads. TP: These systems run themselves to a certain extent, but what metrics are you looking at when you're measuring how well your system's operating? What levels do you have to have? Give me that score of all the things that need to be paid attention to.

Tardigrades, often called water bears or moss piglets, are near-microscopic animals with long, plump bodies and scrunched-up heads. TP: These systems run themselves to a certain extent, but what metrics are you looking at when you're measuring how well your system's operating? What levels do you have to have? Give me that score of all the things that need to be paid attention to.

JM: Whether it's pH, temperature, dissolved oxygen, ORP, basic ammonia, or phosphorus levels, all of those metrics are fairly easy to measure. Most are done by a simple meter or can be measured fairly quickly with a sample pulled from the system. But there do have to be judgment calls made based on what those levels are at, and that's where some of the training can come into speed that processes up and lower that learning curve a little bit to be able to make a better judgment call on what to do with those numbers. So, in addition to that, I would like to clarify that some rudimentary math skills are definitely needed for some of the calculations to be made based on those numbers. It's not rocket science but will be a little more difficult than basic addition and subtraction. There's a bit of a learning curve when it comes to math with running a biological system, and that tends to be one of the most intimidating parts of operators going through their training. But again, it's not something to be afraid of. Anybody can do it; it's a little extra work and a little extra thought that goes into it, but I do want to encourage operators not to be intimidated by the math portion.

TP: The benefits seem fantastic, according to those who have used it. Are there certain times when the biological system produces excessive solids? If so, how do the individual shops handle those?

JM: If it's a conventional activated sludge system where the biomass is suspended in a tank or a basin, those tend to produce more solids. By the general nature of those systems, more solids will be generated as the system runs. The bacteria, as they break down the BOD and COD and nutrients in the system, are basically turning that into new bacteria, so they're reproducing. So BODN, more bugs out, is how it works. So, a portion of those solids and bacteria must be removed daily to maintain a consistent concentration in the system. Those solids are generally allowed to settle and then removed through filtration. This is similar to how solids generated by coagulation and flocculation processes are already removed from the existing system. So, many plants that are retrofitting a biological system into an existing physical-chemical removal system will probably already have that equipment in place. Still, they may need to upsize depending on the solids produced. If they're using a fixed film system where the bacteria grows on a surface, those systems tend not to produce nearly as many solids. They're typically not efficient from a removal standpoint, but they are a little more attractive to metal shops simply because of that lack of solids production. As the biofilm grows on the surface, part of that film will eventually slough off the surface, but that solids production is a fraction of what a conventional activated sludge system will produce.