Going from a 7,000-square-foot powder coating operation to a 70,000-square-foot facility isn’t something done overnight, and managing it doesn’t get any easier.

Just ask Kevin Maas and his brother, Kraig, owners of Maas Brothers Powder Coating in Livermore, California, just outside of San Francisco.

“It’s been a slow progression,” Kevin says. “We started in 1998, and 10 years later, we moved into the space we have now, so it’s been a journey.”

Versatile 70,000+ Square-Foot Facility

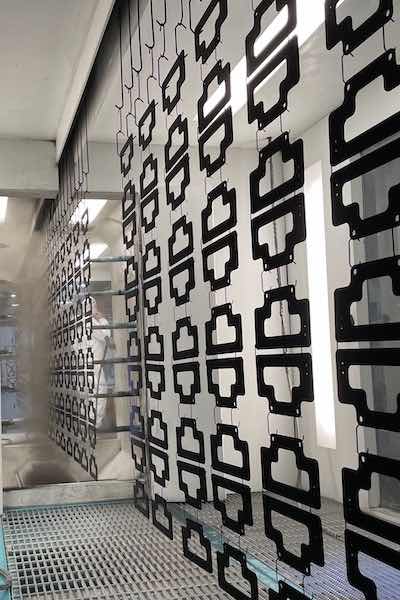

Kevin and Kraig Mass started their powder coating operation in 1998.The 70,000+ square-foot facility has an abundance of space not only for powder coating as long as 12.5 feet in length but also for value-added services such as masking and plugging, light assembly, and packaging.

Kevin and Kraig Mass started their powder coating operation in 1998.The 70,000+ square-foot facility has an abundance of space not only for powder coating as long as 12.5 feet in length but also for value-added services such as masking and plugging, light assembly, and packaging.

Maas Brothers Powder Coating has close to 100 employees to service both high-volume and low-volume customers with two conveyor lines, including a newer system that runs 14 feet a minute.

“We’ve moved a lot of our customers into the conveyorized line because it is more futuristic,” Kevin says. “That’s where we saw it was going, and we can innovate and stay up to speed with all the new things that are being offered. About three or four years ago, we added to our line and extended it to be able to prime or secondary coat.”

The production line starts with a 5-stage closed loop wash/pretreatment system that uses both reverse osmosis and deionization filters to reuse all the water used in the washing process, making it a closed system that is eco-friendly and economical.

Specializing in 2-Coat Needs

The shop's newest conveyor system runs 14 feet a minute.There are several powder coating booths and two IR ovens on the line. For two-coat needs, the first of two infrared ovens serve to pre-gel the first coat, followed by a cooling tunnel that then brings the parts to the appropriate temperature to allow them to immediately receive another coat, nearly halving the amount of time that would otherwise be necessary to accommodate two coats.

The shop's newest conveyor system runs 14 feet a minute.There are several powder coating booths and two IR ovens on the line. For two-coat needs, the first of two infrared ovens serve to pre-gel the first coat, followed by a cooling tunnel that then brings the parts to the appropriate temperature to allow them to immediately receive another coat, nearly halving the amount of time that would otherwise be necessary to accommodate two coats.

The facility’s color-change system can make a switch in between 7 and 10 minutes. The powder reclaim technology saves customers material costs by capturing and reusing up to 50% of powder that would otherwise go to waste.

Overall, Maas Brothers Powder Coating’s two main lines are impressive:

Conveyor Line 1:

- Part Size Limit: Up to 12.5 feet by 2 feet by 5 feet.

- Gas-fueled convection curing oven.

- Two in-line infrared (IR) curing ovens are used for powder pre-gelling and quick curing.

- 5-stage wash process with closed-loop cleaning, washing, and sealing.

- Iron phosphate pretreatment is an environmentally friendly, closed-loop process with zero discharge.

- Automated priming and in-line 2-coat powder coating capabilities, combined with the in-line IR Ovens, means they can handle two-coat needs in one cost-saving turn on the conveyor system.

- Computerized automated spray booths that assure consistency of color and desired film thickness.

- Manual spray gun assist is used to augment automated powder coat guns to handle complex coating needs.

- Powder reclaim capabilities with cyclone technology that recaptures powder for reuse, saving you money on your project.

- Quick color change booth with 7-10-minute color change that is fully automated with quality control checks and external manual touch-up stations.

Conveyor Line No 2:

- Gas-fueled convection curing oven.

- Part size limit: up to 4 feet by 12 inches by 5 feet

- 4-stage washing process with closed-loop cleaning, washing, and sealing.

- Computerized automated spray booths that assure consistency of color and desired film thickness.

- Iron phosphate pretreatment is an environmentally friendly, closed-loop process with zero discharge.

Adding Second Line as a Backup

“Two years ago, we bought another small line which runs at six-foot-a-minute,” Kevin says. “It allows us to back up our main line. At the beginning of Covid, it kind of slowed everything down a little bit, and we’re seeing it picking back up now.”

“Two years ago, we bought another small line which runs at six-foot-a-minute,” Kevin says. “It allows us to back up our main line. At the beginning of Covid, it kind of slowed everything down a little bit, and we’re seeing it picking back up now.”

The shop also has a batch system that can do anything up to 25 feet, which Kevin says handles some walk-ins and smaller jobs.

“We have a hard time turning that down because we’re very fortunate and appreciative of those guys who helped build us up,” he says. “Everybody is just as important to us, whether it’s one piece or a million pieces.”

Kraig says that by continuing to offer batch services, they can partner with customers who are just starting out.

“If we didn’t have batch, we’d miss the opportunity to grow with customers who don’t quite have the volume for our conveyor yet,” he says. “We all want to grow. But we also always want to keep our past business relationships growing, too.”

Yet Maas Brothers Powder Coating is seeking those larger volume customers who need a facility as large as theirs that has the latest technology and speed in its line. The smaller jobs are near and dear to Kevin and Kraig’s hearts, but the operation was designed for mass coating production.

“When you have a 70,000 square foot building, you can’t be walking all over the place with one part,” Kevin says. “We have a good flow and understanding of where our strength is. We’ve done this for a long time; we make all our own fixtures, and we make our own racks. We are very good at getting creative and coming up with ideas.”

Taking a ‘Leap of Faith’ by Entering Coating Industry

The company’s origins go back to when Kevin and Kraig’s father owned a shop as the boys were growing up, and each spent parts of their summers working for their dad. But the coating industry wasn’t for either of them, as they began their career as journeymen carpenters, putting up stud walls and drywall, which Kevin says “we loved doing.”

The company’s origins go back to when Kevin and Kraig’s father owned a shop as the boys were growing up, and each spent parts of their summers working for their dad. But the coating industry wasn’t for either of them, as they began their career as journeymen carpenters, putting up stud walls and drywall, which Kevin says “we loved doing.”

But the brothers decided they wanted to see if they could make it on their own with a coating operation, so they took “a leap of faith,” as Kevin calls it, and cashed in some of their retirement money early and invested in equipment and a shop.

“We convinced ourselves to say, ‘Let’s try this and see how it goes,’” he says. “It was a huge leap of faith. To get a batch operation going, you need to get your name out there, and that is really hard from scratch.”

Kraig recalls they sold everything they owned — extra cars, go-carts, dirt bikes — and cashed in their retirement funds.

“The one thing you can always do is work your hardest,” he says. “If you give it your all, even if it doesn’t work, you can’t get mad at yourself.”

Determined to Grow Their Business

Soon, they had enough work to hire employees, but they didn’t have the money to hire them.

“We worked all the time,” Kraig says. “We skipped lunch. We were determined to make our business work.”

Being located in the East Bay in Alameda County — where SF Bay Area manufacturing thrives — Maas Brothers soon found a lot of commercial customers, starting with the lighting industry. Today, the East Bay is increasingly home to companies in the electric vehicle and EV battery industries and other hi-tech industries that are spurring growth in their functional coatings, which work well on their automated line because of their two-coat capabilities.

In fact, some of the startups make a pit stop at Maas Brothers Powder Coating early in their design engineering process to get guidance on coating their finished products to ease the manufacturing process to help speed production.

“We’ve earned that reputation, and a lot of them come to us for answers,” Kevin says.

Becoming Aggressive in Securing New Business

While the business has grown steadily, Kevin and Kraig are beginning to take a more aggressive approach to market Maas Brothers Powder Coating. They have boosted their sales efforts, and Kevin says they want to double their sales within the next five years.

“There’s a lot of new technology that’s coming out, and we’re always open to that,” he says. “I think the lower temperatures on MDF and wood is something we are looking at because we are always challenging ourselves and taking chances.”

Suffice it to say, Maas Brothers Powder Coating wouldn’t be around if the brothers had not taken a chance and launched the business. It wasn’t smooth sailing the first several years, especially when neither Kevin nor Kraig was taking home regular paychecks in order to keep the company afloat.

“In the early days, my brother and I would walk by each other and not talk to each other all day because we’re trying to focus,” Kevin says. “Everything was on the line, and you’ve got no other way. You can’t go wrong because there is no Plan B.”

From the start, they gained a positive reputation by working hard and focusing on keeping their word — delivering what the customer needed, as promised and on time, which is something they learned as carpenters. The brothers say they valued building long-term business relationships, and today customer turnover remains low. Their more recent push to grow focuses on keeping our long-term relationships strong while building new ones.

“I always tell everyone — including my employees and my kids — that when you’re at your lowest point, pay attention because that’s when you’re going to learn the most,” Kevin says. “As a business owner, you learn something every single day.”