Aaron Johnson was just a few years out of college and working hard in the chemical industry when he spied an opportunity that he just couldn’t pass up. The now-president of Oshkosh Plating Technologies in Wisconsin heard the owner of the shop was retiring, and in 2013 took a quick leap into business ownership.

“I have been learning ever since,” says Johnson, who runs one of the premier shops in the U.S. as it provides zinc plating services to customers located in and around the Fox Valley area of Wisconsin.

“I have been learning ever since,” says Johnson, who runs one of the premier shops in the U.S. as it provides zinc plating services to customers located in and around the Fox Valley area of Wisconsin.

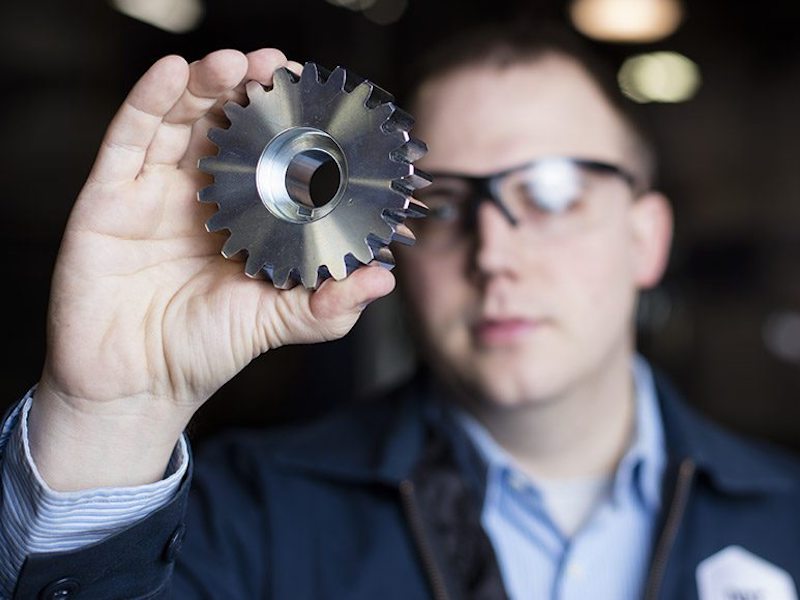

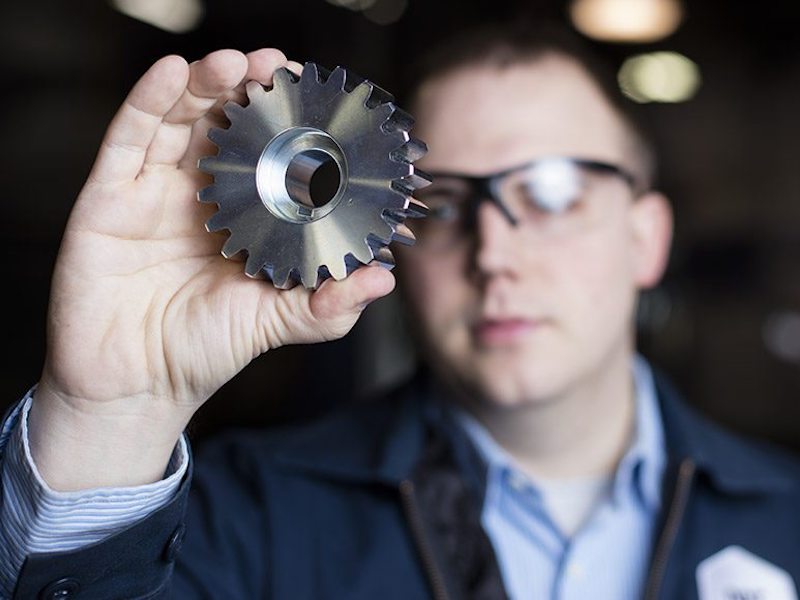

Oshkosh Plating operates both rack and barrel line processes. The rack line is capable of handling parts 110 inches long by 58 inches high by 30 inches wide and weighing up to 250 pound, giving them the capability of zinc plating very large non-uniform parts.

In addition, they have a manual barrel line that handles production runs of varying sizes while paying close attention to quality.

“We are able to bake for hydrogen embrittlement relief on each line,” Johnson says. “We also offer packaging and direct shipping to our customer’s customers if requested.”

FOCUSES ON AGRICULTURE, HEAVY MACHINERY AND CONSUMER PRODUCTS

Oshkosh Plating has been in business since 1979. Johnson is the owner and president, and Clayton Emons is the plant manager. The shop focuses on agriculture, heavy machinery and consumer products parts.

Oshkosh Plating has been in business since 1979. Johnson is the owner and president, and Clayton Emons is the plant manager. The shop focuses on agriculture, heavy machinery and consumer products parts.

One lesson Johnson has learned is to continually improve the equipment and look for new finishing and coating opportunities.

“We have been improving our current zinc lines in the last couple of years, including new rectifiers, timers, feed pumps, improving rinses and adding batch ovens,” he says. “We also added a painting booth and a blasting cabinet.”

A big addition came when Oshkosh Plating recently added Cerakote coatings and aluminum oxide blasting; the former being a polymer-ceramic composite coating that can be applied to metals, plastics, polymers and wood to enhance a number of physical performance properties.

The process involves degreasing each metal part for 20-30 minutes, sandblasting until it is no longer shiny, mask and rack the part, gas-out the metal parts by heating them in the oven to get rid of moisture and solvents, prep the part for coating, spraying on the coating, air-drying for 15 minutes, and then curing in the oven for 1-2 hours.

“We are continually improving and working hard each day to exceed our customer's demands,” Johnson says.

LAUNCHING CRAFT CUSTOM COATING IN 2019

One of those ways was to launch Craft Custom Coating in 2019, which is a separate business run by Johnson at the Oshkosh Plating site that performs the Cerakote process.

One of those ways was to launch Craft Custom Coating in 2019, which is a separate business run by Johnson at the Oshkosh Plating site that performs the Cerakote process.

“We took our experience and knowledge of metal finishing and we started customizing one of a kind pieces using Cerakote and hydrographics,” he says. “We take our Craft very seriously, and we are certified in both Cerakote and hydrographics. We stand behind our work and have a ‘Covered by Craft’ warranty on all the work that we do.”

Another of the other ways Oshkosh Plating has been able to grow has been by bringing on staff that fit their culture, and by providing opportunities for those who many not have a smooth path into the workforce. The company works with their local justice system to employ people who have been incarcerated and are re-entering the workforce, as well as working with the Wisconsin Department of Workforce Development and its Veterans Employment Services division to provide employment for returning veterans transitioning to the civilian workforce. They also coordinate with the World Relief Fox Valley and other area organizations resettling refugees.

The company has 25 employees working three shifts, but recruiting employees from a wide range of backgrounds has enabled them to maintain the necessary workforce during a time of low unemployment in the area. As part of the company mission, employees are involved in a range of decision-making processes, such as quality goals, safety issues and hiring decisions.

The company has 25 employees working three shifts, but recruiting employees from a wide range of backgrounds has enabled them to maintain the necessary workforce during a time of low unemployment in the area. As part of the company mission, employees are involved in a range of decision-making processes, such as quality goals, safety issues and hiring decisions.

“The thing that really makes me happy is when we hire an employee who has very little previous manufacturing skill and a complicated past, and I see them take ownership of the plating process, show up to work every day and improve their life,” Johnson says. “Some of these employees utilize us as a stepping-stone, and some move up internally.”

WORKING WITH EMPLOYEES ON LIFE SKILLS

Oshkosh Plating also works with employees on life skills to help them achieve their long-term goals, such as buying a house or applying for college. Johnson said that approach to employee involvement is a major reason for the success of the shop.

“We are going to continue to find ways to meet our customer's metal finishing needs,” he says. “We are looking for processes that we can add. This continual growth will probably lead to an expansion in the next few years.”

Some of Oshkosh Plating’s top suppliers are John Schneider and Associates, Yuken and Advance Chemical Hydrite

Visit oshkoshplating.com.