Queen’s University in Kingston, Ontario, in Canada has launched a new Carbon to Metal Coating Institute.

C2MCI international, interdisciplinary team led by Cathleen Crudden, Canada Research Chair in Metal Organic Chemistry and professor in the Department of Chemistry, received $24 million in support from Canada’s New Frontiers in Research Fund to advance this research. Their novel approach to protecting metal surfaces relies on a molecular primer capable of slowing or preventing oxidation and ultimately, degradation of metals.

WATCH THE VIDEO ABOVE

During the launch event on May 25, Queen’s Principal Patrick Deane highlighted many years of research that built the foundational knowledge to advance this new solution.

“The launch of this Institute is very exciting,” Deane says. “The research associated with it will be truly transformative. This will have a positive impact on our environment and helps deliver on the university’s commitment to the United Nation’s Sustainable Development Goals.”

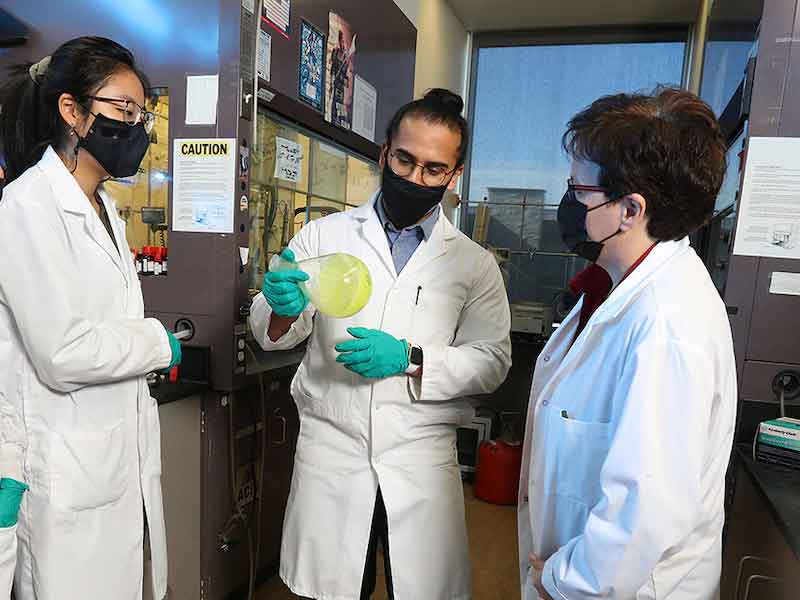

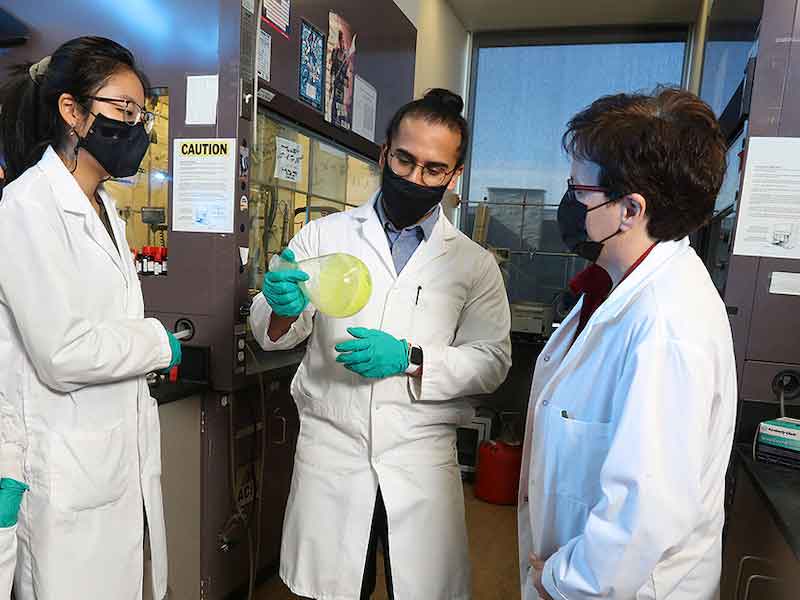

Catheen Crudden welcomes team members and guests to the Carbon to Metal Coating Institute launch event.As the new research could enable production of more resilient infrastructure for transportation and green energy, it supports Canada’s transition towards a more environmentally friendly economy. More resilient metals will reduce the demand for metal extraction processes, lowering greenhouse gas emissions, and this will minimize leaching of contaminants into the environment from corroding metals.

Catheen Crudden welcomes team members and guests to the Carbon to Metal Coating Institute launch event.As the new research could enable production of more resilient infrastructure for transportation and green energy, it supports Canada’s transition towards a more environmentally friendly economy. More resilient metals will reduce the demand for metal extraction processes, lowering greenhouse gas emissions, and this will minimize leaching of contaminants into the environment from corroding metals.

Potential applications of the new method also include designing new microelectronics manufacturing processes to prevent the breakdown of microchips in electronic devices such as computers and phones, and improving precision, safety, and effectiveness of nanomedicine therapies, particularly in cancer treatment. If implemented, these coatings could help countries save billions across industries, each year.

“Chemists have known for a long time that carbon-metal bonds can be very strong, but our group at Queen’s was the first one to look at whether this works to create strong coatings on metal surfaces as well,” Dr. Crudden says. “This work was called game-changing by chemistry and physics experts”.

Dr. Crudden emphasized the importance of collaborating with academic, clinical and industry partners in countries like Japan, United Kingdom, USA, Finland, and Sweden, ranging in expertise and from basic to applied sciences. The mixture will allow the new institute’s translational work from lab research to real-world trials to large scale production.

The creation of the Carbon to Metal Coating Institute will provide the team with the administrative infrastructure to advance research, develop high qualified personnel, and support the international network of collaborators. It will also provide enriched interdisciplinary and international training opportunities for undergraduate, graduate, and postgraduate students.

One of the strengths of the new institute is that it embeds equity, diversity, and inclusion (EDI) principles into its processes – for example, it will have allocated budget to foster EDI initiatives and engage students from equity deserving groups.

“We believe EDI is essential for a successful project,” Dr. Crudden says.

For more information on the Carbon to Metal Coating Institute, visit https://www.carbon-2-metal-institute.queensu.ca