There are multiple methods that can be employed to remove the burrs from a metal part that has undergone the laser cutting process.

In this article, we will share the best practices that can be used for the perfect removal of burrs from the metal part.

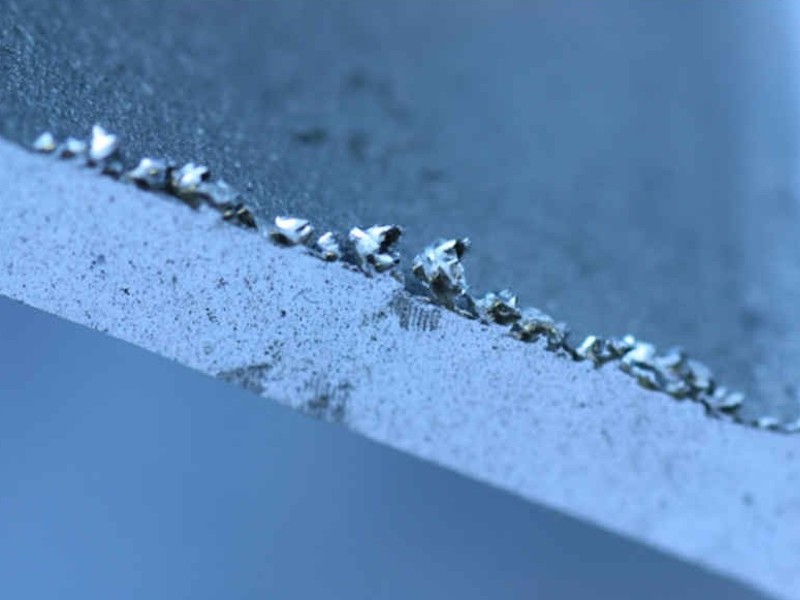

The process of cutting metals using the laser involves applying a high-energy beam on the metal parts. This process will result in the melting of the metal parts at the point of contact of the laser beam. During this process, some of the material will get stuck to the edges and the sides of the metal parts. There are gases involved in the laser cutting process that helps to remove the molten metal from the metal part. Some of these metals in the molten state may get sticked to the edges of the metal. Thus, burrs are formed on the part during the laser cutting procedure.

The process of cutting metals using the laser involves applying a high-energy beam on the metal parts. This process will result in the melting of the metal parts at the point of contact of the laser beam. During this process, some of the material will get stuck to the edges and the sides of the metal parts. There are gases involved in the laser cutting process that helps to remove the molten metal from the metal part. Some of these metals in the molten state may get sticked to the edges of the metal. Thus, burrs are formed on the part during the laser cutting procedure.

Multiple Varieties of Burrs

Different varieties of burrs will be formed on the metal parts during the laser cutting procedure. They are given below.

The process of piercing a metal sheet using the laser will result in splashes. These splashes will get settled on the edges of the metal part resulting in burrs.

The gases that are used during the laser cutting procedure are capable of creating an oxide layer on the metal workpiece. This oxide layer will make the metal corrode later. So, this oxide layer must be removed to improve the life of the metal part.

When the metal workpiece is put into mechanical stress, it will result in the formation of mechanical burrs.

Slag is nothing but the other name for thermal burr. The process of cutting metal using a laser created lots of heat. The burrs created by this heat are called thermal burr.

Vibratory Deburring Machine

The vibratory deburring machine is one of the best options to remove burrs from small and medium-size parts. It comes in various sizes. So, you can easily select one according to your workpiece requirements.

The principle of vibratory motion is used in the working of the vibratory deburring machine. There will be a container in the machine. The operator can load the metal parts along with the abrasive media for deburring. There is a motor connected to this container. It is the motor that will make the container vibrate. So, the vibration of the container will help the parts to rub against the tumbling media for deburring.

The vibratory deburring machine comes with a multitude of benefits. These advantages are shown below.

- The vibratory deburring machines often come at an affordable price. You need to make a one-time payment for the machine. You can also invest in a tumbling media with high life. Thus, this solution will prove to be a cost-effective one.

- You can use the vibratory deburring machine for deburring multiple laser-cut metal parts at a time. So, burr removal will happen for more parts at the same time. It will help to improve your productivity and efficiency.

- The maintenance is very less for all the vibratory deburring equipment. The cost of maintenance is also very less for these deburring machines. Thus, it will be more profitable in the long term run.

- The different varieties of abrasive tumbling media include stainless steel media, plastic media, ceramic media, etc. All these media types are offered in different sizes and shapes. Thus, you can easily get the media of your choice for deburring.

- The vibratory deburring machine often guarantees high-quality burr removal from the metal parts. You will get the best finish on the part as the output.

Belt Grinding Machine

The belt grinding machine is the best choice for deburring large and big laser-cut metal workpieces. If your business deal with large parts, then you can consider investing in one of these machines.

This machine consists of an abrasive belt. The metal part to be deburred is kept on a tray that is located under this abrasive belt. The operator can vary the abrasiveness by changing the belt. Once you start the grinding machine, you can keep the metal part on the tray. The belt will rotate in a circular fashion and will be in contact with the metal surface to remove the burrs.

There are lots of benefits to using this grinding machine for deburring large parts. All these benefits are listed below.

- You can get belts of different abrasiveness. You can use a higher abrasive belt to remove heavy burrs from the part and a belt of lower abrasiveness for removing minor burrs. Thus, it helps to remove burrs of all sizes.

- The belt grinding machines are capable of providing a top-quality finish on the parts after the burr removal. Thus, it guarantees a high-quality part at the output. The operator must make sure to use the belt of right abrasiveness for best results. You may have to use multiple belts on the same part for best results.

- The belt grinder machine is easy to use. There are no complex operations involved. So, anyone can easily operate the belt grinder with the help of the manual.

- The abrasive belts used in the grinders come with very large grinding areas. So, you can easily deburr large metal parts using this machine.

You need to select the right type of deburring machine along with the right media to remove the burrs perfectly. It is good to invest in media that can be used more times. It will definitely prove to be a cost-effective solution in the long run.

Zhengzhuo Zhang is a Mass Finishing Consultant for Inovatec Machinery Mass Finishing. Visit http://www.inovatecmachinery.com