Automotive fans and lovers worldwide often ask themselves how the objects of their adoration are made.

In this article, we’ll uncover how one of the automotive icons is painted: the story of Jaguar Land Rover Defender.

Luxury and SUV carmaker JLR has been a wholly-owned subsidiary of India-based Tata Motors since 2008. The origins of Jaguar can be traced back to 1922, and the first Land Rover was unveiled at the Amsterdam Motor Show in 1948.

Made in the Newest JLR Plant

Ján LilkoJLR Defender is produced at the newest JLR manufacturing plant near the historic city of Nitra in Slovakia. The manufacturing plant is built for 30 jobs per hour (jph). The manufacturing site consists of Body-in-White (BiW), Paint, Trim and Final, Energy Centre, Training Academy, Logistics, and Administration offices with over 4,500 direct employees.

Ján LilkoJLR Defender is produced at the newest JLR manufacturing plant near the historic city of Nitra in Slovakia. The manufacturing plant is built for 30 jobs per hour (jph). The manufacturing site consists of Body-in-White (BiW), Paint, Trim and Final, Energy Centre, Training Academy, Logistics, and Administration offices with over 4,500 direct employees.

JLR Paintshop covers 52,000 m2 with a current production output of 30 jph. It is divided into four height levels:

- The ground level is dedicated to sealing, sanding, polishing, and visual inspection.

- Level 4,7 m contains conveyors and conveyor loops.

- Level 9,5m is dedicated to automatically applying primer, base coat, clear coat, and curing ovens.

- Level 14,7 m contains air handling units, gas burners, and auxiliary equipment.

The automation consists of 56x application robots and 36 robot openers in total. Nitra Paintshop has up to 18x types of colors depending on the current model year. Of course, colors like black, white, and silver comprise the largest part of the running production.

Defender in Colours.

Defender in Colours.

Automatic Storage and Retrieval System

Unpainted and painted Defender car bodies are stored in a fully automated Automatic Storage and Retrieval System (ASRS) warehouse. The ASRS system can insert and retrieve one car body every 12 seconds. Custom-designed tooling sets are fitted to the doors, bonnet, and tailgate to ensure all are safely locked in a designated position during the next stages of the paint application.

Automatic Storage and Retreival System.

Automatic Storage and Retreival System.

Metal surface pre-treatment has a critical impact on the final coating quality. If this process is underestimated, it can have negative consequences for final quality. It is important to choose the correct type of pre-treatment technology for each material base and a specific type of subsequent application. The duration of the pre-treatment and the subsequent processes are also crucial to the quality.

The pre-treatment process in Nitra Paintshop consists of 13 stages of dipping and spraying chemical sub-processes suitable for mild steel, zinc-coated steel, and aluminum. The first stages of the process ensure the body is fully cleaned to remove general contaminants, followed by a thorough chemical cleaning of the metal surface.

The final stages are the phosphate and the passivation processes. This converts the metal surface by depositing a crystalline coating required for good adhesion of the subsequent e-coat layer.

Rotation dipping in e-coat.

Rotation dipping in e-coat.

E-Coat Applied to Exterior and Interior

The electrophoretic deposition (e-coat, KTL) of the paint is applied on the exterior and interior surfaces of the car body. Car bodies are negatively charged, and the e-coat bath solution is positively charged via anode rows along the walls of the e-coat bath.

The paint particles are attracted to the body and form a uniform layer of paint to the required thickness levels. The car body is then cured at 180°C. The e-coat layer is the key process delivering the anticorrosion properties. At the desired thickness, the electrical attraction ceases as the paint coating insulates the negatively charged body. Process efficiency is over 92%.

The pre-treatment and e-coat processes are carried out by the rotational process called Ro-Dip, which delivers significant cost reduction, less material usage, lower energy consumption, and improved quality results compared to conventional dipping processes.

Automatic Sealing Application.

Automatic Sealing Application.

The PVC sealer is applied on a fully e-coated Defender Body-in-White (BiW). The PVC sealer has multiple functions. It is used to fill the gaps in the product to prevent water ingress or moisture from seeping into the car body. It also provides a significant protection against corrosion. PVC sealer is applied robotically on the joints and seams.

Then, noise, vibration, and harshness (NVH) protections are applied automatically. The final stations of the PVC sealer line are the Under Body Sealing (UBS) and Interior Seam Seal (ISS) robot cells.

Cosmetic Sealing Application.

Cosmetic Sealing Application.

Cosmetic Sealer Applied on Difficult Places

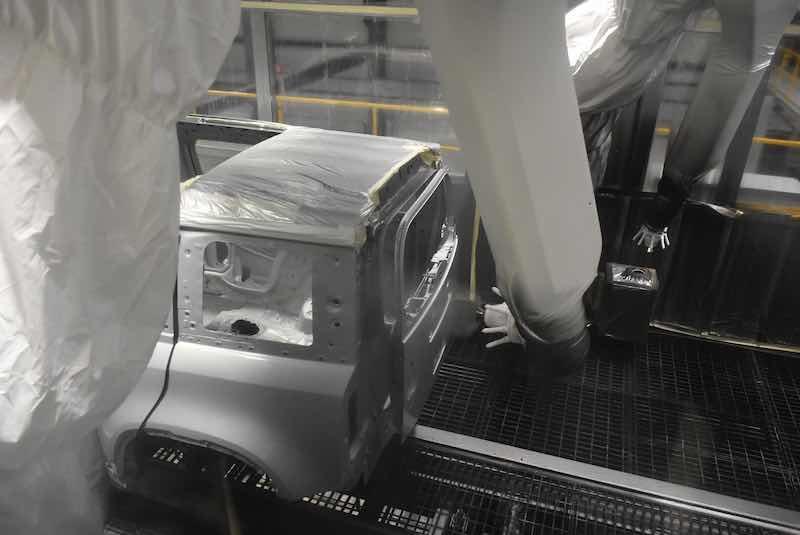

Cosmetic sealer is applied manually on difficult places, e.g., roof ditch or the hem flanges. Car bodies are then routed via the inspection and rectification decks to prepare a defect-free car body before the painting applications. Water-based primer applications consist of 16x painting robots.

This application aims to improve the adhesion properties, fill the surface irregularities, improve the final look of the car body, and create an important interface between the next layers. An important feature of the primer layer is protecting already applied layers against ultraviolet radiation that can damage the coating. It also increases corrosion resistance.

Once the vehicle has been cured through the primer oven, the paint finish is inspected and rectified for defects.

Primer Application.

Primer Application.

The next layer is the base coat or color. It is the first thing the customer notices on the car. The basecoat visually completes the overall impression and teases customers into buying the car. It is one of the most important characteristics affecting purchase decisions, and designers, manufacturers, and car dealers are very well aware of it. All internal and external surfaces are painted automatically. The water-based basecoat then passes through a short inter-coat flash-off oven (ICFO) to remove the excess water before the clear coat application.

Base Coat Application.

Base Coat Application.

1K Clear Coat Automatically Applied

One-component (1K) clear coat is automatically applied internally and externally over the basecoat bodies and cured in the topcoat oven at 140°C. JLR Nitra Paintshop has a continuously running main painting lines with ‘line tracking ’ system and Contrast roof facility with ‘stop and go’ painting system – the car body stops at a precisely determined place in the painting booth for the painting robots to initiate the automatic painting process.

Clear Coat Application.

Clear Coat Application.

Defender in the Oven.

Defender in the Oven.

Interior and exterior primer, base coat, and clear coat applications happen inside closed application booths with a controlled temperature, humidity, and air downdraft. The air flowing through the booths is cleaned from the overspray in a dry scrubber separation system underneath the application booths. This process is water-free, with a fine limestone powder used as the air filter. This sustainable technology significantly reduces heat consumption, power consumption, CO2 consumption, and odor and does not create paint sludge.

Paint Supply System.

Paint Supply System.

Dry Paint Separation System with Limestone.

Dry Paint Separation System with Limestone.

The painting process generates a significant number of various pollutants. Therefore, multiple special devices are placed to maintain sustainability. TAR, a recuperative thermal oxidizer, purifies the exhaust air from the curing ovens. It is done by thermal oxidation of the pollutants contained in the exhaust air. The TAR incinerator is designed as a compact unit with a combustion chamber and an integrated heat exchanger. TAR efficiency of air purification is up to 99%.

Flame in TAR.

Flame in TAR.

After the painting processes, operators inspect the car body at the Final Buy-off deck for any paint imperfections and defects - if any are found, the operators can rectify them. If possible, the defect will be lightly sanded and then polished until a satisfactory appearance is achieved.

Visual Inspection.

Visual Inspection.

Injecting Water-Based Anti-Corrosion Wax

From the Final Buy-off deck, the car body is heading into the Wax station. Water-based anti-corrosion wax is injected into particular cavities of the door sills. The main purpose of the wax application is to prevent corrosion from occurring in the areas of the vehicle that may be subject to immersion in water, enabling Defender to achieve a wading depth of up to 900mm.

Defender is produced in 3x different wheelbases: 90, 110, and the longest version, 130. It has received over 75 awards worldwide since its re-introduction in 2020, for example, Car of the Year, Design of the Year, and SUV of the Year.

Of course, this phenomenal achievement would not be possible without the designers' creativity, the technical skills of manufacturing engineers, the dedication of suppliers, and the craftsmanship of manufacturing workers.

Defender.

Defender.

Ján Lilko, PhD., MBA, is ME Paint Programmes and Facilities Manager at JLR Slovakia. Visit www.jaguarlandrover.com